Launch Day Review

Introducing SRAM Maven Brakes

How Much Brake do you Need?

Consistency, power, modulation, reliability: these are what most of us look for in brakes. Depending on the kind of riding you do, weight could enter the equation and of course ergonomics that work for you are vital. For the riding we do around here, modulation and power are important, and one without the other is of little use. These new brakes from SRAM satisfy all of our needs, with an emphasis on more power, with less force required at the lever to generate that friction.

Nothing looks as steep in photos. Jesse Melamed testing Mavens on some of Squamish's finest. Photos - SRAM

In this is sort of predicament, consistent power, modulation and heat management might come in handy.

We may not normally think brakes help us go fast but of course they are essential. As any F1 driver will tell you, powerful brakes let you carry speed deeper into corners so the time you spend slowing down is reduced. Obviously they are useful in panic situations as well and for providing control in challenging conditions. The more challenging and steep the trails are, the more you need from your brakes.

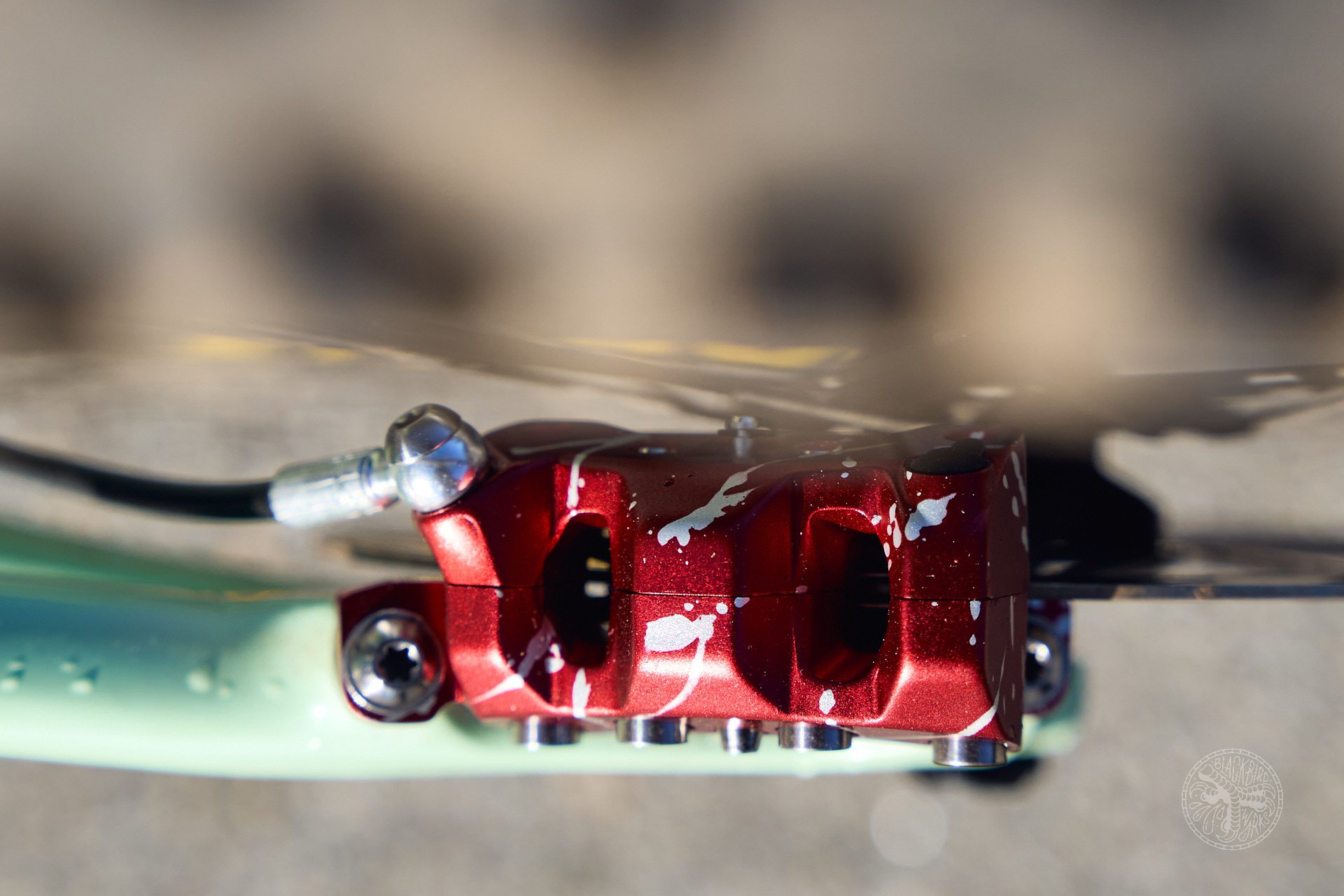

The four bolts clamping the two halves of the Maven caliper together (made of Titanium in the Expert & Ultimate models) are there for stiffness and possibly heat management to some extent. I wanted to crack my testers open but I was advised not to, at least for now...

The bolts mean the brake pads are inserted from the bottom but they go in and out incredibly smoothly. There are both sintered (metallic - on the left) pads and organic, which are now also available for Codes for quieter and more consistent performance at some cost to braking bite.

Tailoring Power

SRAM tells us their measurements suggest the Maven Ultimates generate 50% more braking force than Code Ultimates. But the Mavens aren't all about maximum braking force. There are two main changes riders can perform to make brakes generate more power: rotor size or pad compound. If you are riding Codes for long steep downhills, chances are you are close to maxed out for those choices with metallic pads and 200mm rotors or maybe a 220/200 front rear combo. SRAM's HS2 rotors also produce 7% more power than the Centerlines. The promise of Mavens is that you can tailor the power to your needs, and SRAM now makes organic pads for both Codes and Mavens to help with that process. The Maven Expert kit comes with both metallic and organic pads and four rotors: 1 x 220mm, 2 x 200, and 1 x 180, so riders can achieve the feel they are looking for, which might be below knob-ripping levels.

This power is generated by a relationship between the master cylinder piston and the two pairs of large caliper pistons measuring 19.5 and 18.0mm in diameter. In contrast, Code pistons are 16 and 15mm. While SRAM hasn't revealed the size of the master piston, they tell us that power is determined by the relationship between these pistons and that these have "superior optimization of this ratio."

SRAM also says that every 20mm jump in rotor size represents a 14% jump in power, which means going from 180mm to 220 produces a 28% jump in power. The PR copy also talks about rotor discolouration and what that says about your size choice:

Browned or bronzed discoloring means the size is optimal.

Purple or rainbow discoloring means your rotors are running too hot and sizing up would be suggested.

No distinct discoloring would suggest they aren’t getting hot enough and sizing down would lead to optimal performance.

Heat is not the Enemy

SRAM points out that while too much heat degrades performance, the same can be said of rotor calipers that are too cool. The larger thermal mass of these calipers takes longer to heat up, but it also takes more time to cool down, which SRAM says will keep your brakes in the sweet spot for longer. Peaks and valleys are the enemy of brake performance and with consistent temperatures "performance reaches totally new levels."

The levers resemble the new Code Stealth levers, with the hoses steered toward the bars for a cleaner look but with a larger master cylinder reservoir. Both the reach and contact adjustments work easily.

The calipers are big hunks of aluminum with four burly bolts clamping them together. All that metal is no accident; managing heat is a huge component in braking consistency.

On The Trail (comparison to Code)

My time with the Mavens before launch was short so I was planning to ride them exclusively until then, to gather as much data as possible. Fortunately, an opportunity came up for a ride on a set of Codes which provided a valuable comparison - and a frightening one. The difference was so great that when first dropping into the trail, I felt like I had no brakes. I did, of course, but it took so much more clamping force from my finger and lever throw, that I overshot the first few moves and almost ended up in the rhubarb. Before long, things felt back to normal but those first few minutes made me realize how much less strength is required for the same braking force on the Mavens compared to a set of well-maintained Codes. The comparisons weren't perfect but there were factors on either side that may have cancelled each other out. The Codes were on a Norco Sight VLT that weighs over 55lbs but it's equipped with 220 and 200mm SRAM HS2 rotors, while the Yeti SB160 the Mavens are mounted on is 20 pounds lighter and has 200 and 180mm rotors.

Chris Mandell struggling for traction with his wheels off the ground.

I wondered if extra power would be detrimental in any way. In fact I quickly adjusted to the extra clamping force and became reliant on it, but another rider I've spoken to found he was almost launched off the bike a couple of times because he wasn't expecting to stop so quickly. I wasn't feeling on my game in my most recent ride on the Mavens, but they were a contributing factor that allowed me to ride relatively well.

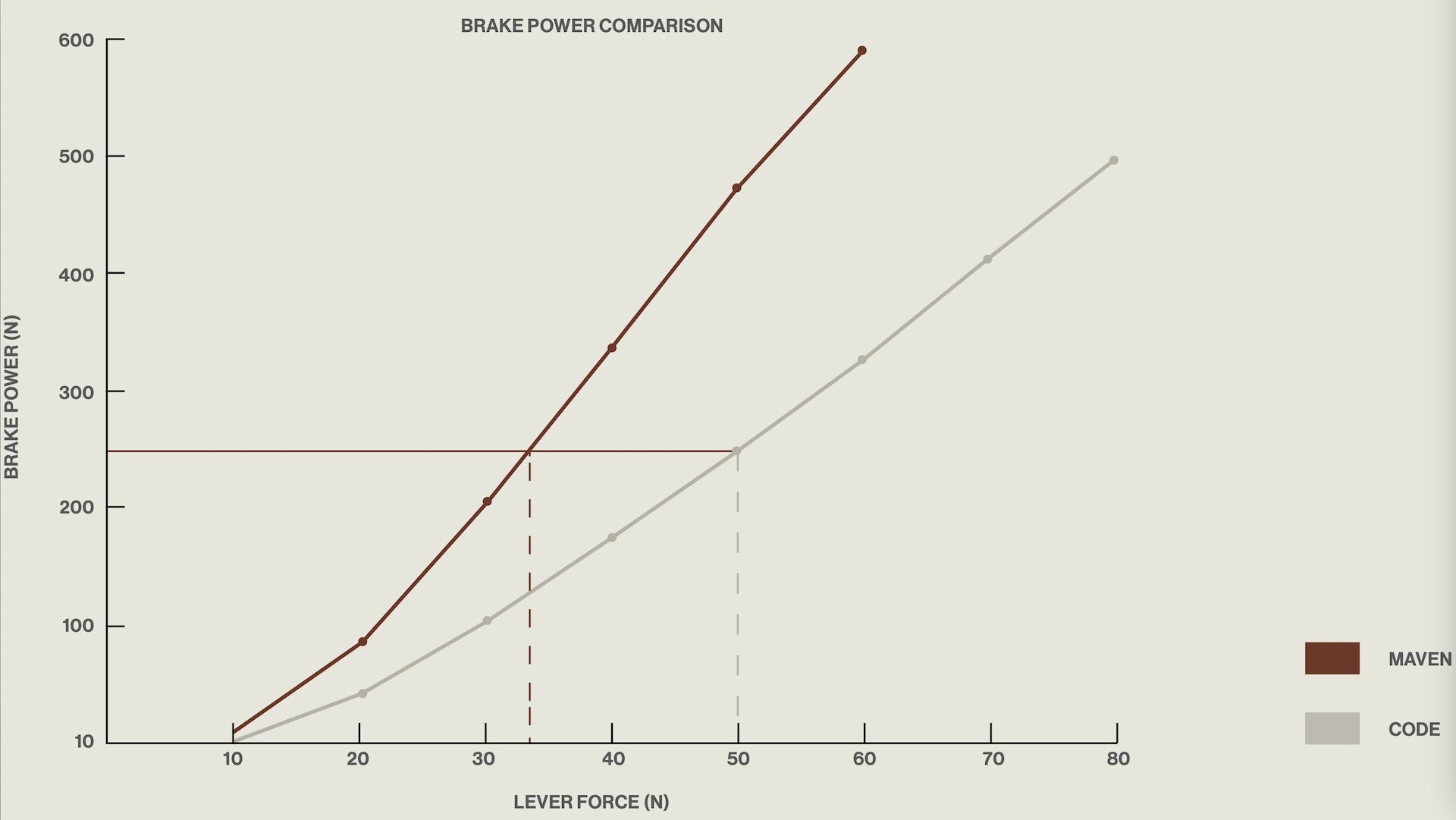

These are SRAM's figures but based on my experience I have no reason to doubt them. At ~33N of pulling force at the lever, you can generate about 125N of braking force with Codes or about 250N of force with Mavens. That will keep your hands a little fresher on a mammoth descent - like Mt. 7 Psychosis perhaps?

Modulation

Today we rode an exposed section of treacherous, bench cut technical single track with slick and wet off camber rock slabs. Trevor Hansen was in front of me and his rear tire was sliding regularly, understandable considering the terrain and the conditions. I tried to see if I could ride the same line without any slippage at all and go the same speed. This was surprisingly easy with the Mavens. I wouldn't say these are remarkable in terms of modulation or even much better than Codes but in practice I find it easier to control and feather the Mavens. It feels to me that the reason for this relates to the increased braking force generated by a given amount of lever force. Smaller muscles are better at precision and reduced force from your finger seems to make it easier to get your wheels to the edge of traction without going over. Beyond muscle sizes, when your grip strength is close to the limit or your hands are tired, sensitivity suffers. In this case, power seems to aid modulation significantly.

SRAM would give additional modulation credit to a modified version of their SwingLink lever architecture, which changes the leverage rate progressively throughout the stroke, ramping up toward the end like an air shock.

This is one of those situations where technology that is advantageous to the best riders in the world is every bit as useful to Joe Average riders.

What Kind of Fluid?

In 2022, without much fanfare, SRAM launched the DB8 brake. It looks familiar to anyone who has seen recent SRAM brakes, but it uses mineral oil instead of DOT fluid. The stated objective at the time was lower maintenance. SRAM recommends bleeding DOT brakes at least yearly while mineral oil can remain in service longer without a significant reduction in performance. The DB8s, like the Mavens, use a different bleed kit, likely to prevent accidental cross contamination, and are supposed to be filled with Maxima's green mineral oil, which was co-developed by SRAM. I'm relatively neutral in the fluid wars but I appreciate the less caustic nature of mineral oil on both skin and paint.

If you look closely, the bleed port at the lever is labelled, just in case you forget.

For Maven to meet our requirements as a mineral oil brake, we went through many seal material iterations to find the most heat resistant compound. Formulated to work with our co-developed Maxima Mineral Brake Oil, this proprietary seal material retains its elastomeric properties to maintain air tight sealing regardless of extreme braking heat or low atmospheric temps. In other words, the material is able to regain its original shape when a load is removed from it. Through testing it was determined that mineral oil offered the best performance (outperforming DOT versions) while also offering desired lower maintenance qualities.

- SRAM PR materials on the choice of mineral oil instead of DOT fluid for the Maven brake.

Click through for five views of the burly SRAM Maven caliper.

Expert Kit and other Trim Levels

The Expert kit is a big box of brakes with all the hardware you need for installation, a "Pro" bleed kit with fluid, 4 rotors (220mm, 200mm x 2 and 180mm) and a full set of both organic and metallic brake pads. There is also a little purse for your spare rotors.

Chris Mandell pointed out that you shouldn't use different brake pads with the same rotors, which is why the kit comes with two sets of rotors and two sets of pads. At a microscopic level, your brake pads aren't actually in contact with the steel of your rotors. The braking surface consists of material deposited on those rotors by the brake pads, meaning they won't play well with other pads. I'm too frugal to get rid of perfectly good rotors so I clean them with isopropyl alcohol or brake cleaner and occasionally some heat when I'm switching to pads of a different composition but SRAM does not recommend doing this and certainly their pro racers don't abide by it.

The Expert kit is a big box of brakes with all the hardware you need for installation, a bleed kit with fluid, 4 rotors (220mm, 200mm x 2, 180mm) and a set of both organic and metallic brake pads. There is also a little purse for your spare rotors. Images - SRAM

One large box of braking goodies.

If you are considering making an aftermarket Maven purchase, get on your horse. These kits are being made in limited numbers and will save you a bundle, despite their 600 USD / 700 EUR / 600 GBP price tag.

The Expert kit isn't cheap but if you are buying the brakes in the aftermarket they are actually great value at 600 USD, at least compared to the Ultimate set, which are 300 USD per end, without a rotor or bleed kit or the little rotor case. It does come with an MMX clamp and bracket but not adapters for your caliper. The Pro bleed kit that comes with the Expert kit is 111 USD on its own but there are two lower priced kits available (63 and 74 USD).

The included pro mineral bleed kit would cost 111 USD on its own. For 600 USD you get a stack of product that would cost you about 1000 USD on its own - and fancy red calipers. This is a limited run however and I'm told that once they are gone, that's it. I wasn't able to find out how many kits are available. Images - SRAM

You didn't even know you needed a little case for your rotors, did you? Maybe some CDs in there as well.

Purchasing everything that comes in the Expert kit separately will be a pricy endeavour with four rotors coming to around 250 USD and an extra set of pads 54 USD, you are looking at around 1000 USD without the little rotor bag or the red anodizing.

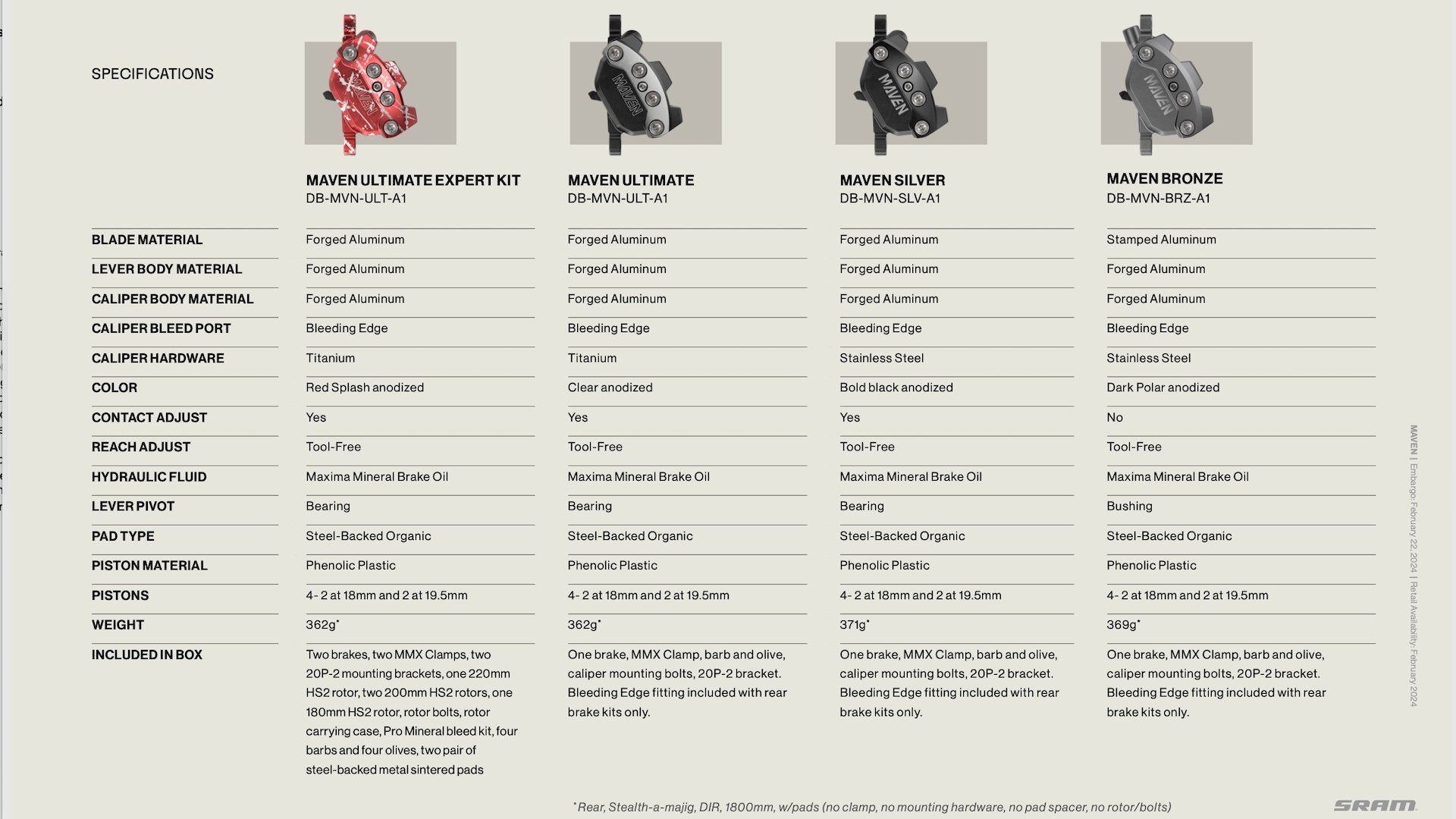

Beyond those top levels, the Silver Maven is priced at 265 USD per end and the Bronze at 185 USD (full price list in an image below). The Bronze lacks a contact adjustment dial, but I can't speak to the performance of anything below the Ultimate until I try them.

The Maven Ultimates are identical to those that come in the Expert kit, aside from the red caliper.

These Ultimates were on Chris Mandell's bike.

Maven levels and specs. Scroll for pricing in USD, EUR and GBP.

You don't need a Phd in Math(s) to see the relative value of the Expert kit.

The Verdict (so far)

At one point I felt like I had a bit of wandering bite in my rear brake after some fast shuttle laps but I'll need some more testing to confirm that. Otherwise these have been incredible brakes. My hands feel fresher, I can feather very well, significantly better than Codes, and if I need a lot of stopping power in an instant, it's all there. The weight penalty of Maven Ultimates (364g) over Code Ultimates (284g) is around 80g in the rear or 150g total (since fronts have shorter brake lines) or about as much as 1/4 the volume of water in your 600ml water bottle. I'll take that penalty for better braking every single time.

I love these on the Yeti I'm testing but they would also be amazing on my Sight VLT with its extra heft. I'm very happy with my Hope Tech 4 E4s so they aren't going anywhere, (the Mavens generate significantly more power in my estimation while the Hopes have finer modulation) but the Codes on my VLT may be replaced.

Comments

HMBA106

2 months ago

Not to be a downer but the fact that they’re selling an “expert kit” that, once sold out, will cost literally 1.67 times as much (getting close to double) goes to show you how ridiculous sram MSRP is. Fortunately for them, most brake components have a wear interval, whether in the short or long term. Oh well, interesting marketing move.

Reply

AndrewR

2 months ago

@Cr4w: I am 210 lbs/ 6'2" and spend my life trying to explain why my bike has 220 front/ 200 rear rotors on Code RSC (including on my Optic).

The Mavens are awesome, I have been on them for about nine months and now run 200 mm front/ 180 mm rear HS2 rotors on my Arrival 170. Earlier in the summer I was running 220 mm front/ 200 mm rear HS2 which were fine for the high speed hoonery that is 80% of Canmore's trails or the plunge-shut it down-drift-plunge technique that is the fall line trail method on some of the trails that 'don't exist' (nudge wink - you know what I mean).

But a visit to Whistler, during an epic period of wet weather in Oct '23, reminded me that when it is steep, technical and slower (and liberally strewn with roots and slippery rock) that there is such a thing as too much power and hence I dropped the rotors down a size for a little more between the 'slowing' and 'locking' the rear wheel.

They just feel 'more' in every way. I don't notice the initial lever effort and as the article states there is so much (useable) power on tap that one is braking so much harder, later and more effectively for far less effort overall.

I think you will like them.

Reply

Cr4w

2 months ago

I like more. More is good. At our size rarely do we get to the experience "too much" the way most people do then settle into a happy middle ground. We go from the latest max to the subsequent latest max.

Reply

[email protected]

1 month, 3 weeks ago

What is the level of effort required to pull the levers? Saw a review Dale Stone. To paraphrase he says the brakes are amazing but the effort in lever pull is significant to the point that he had hand extreme hand fatigue.

Any insight?

Reply

Cam McRae

1 month, 3 weeks ago

I've seen that video Hafez. I believe Dale is incorrect and it's possible that he knows this. We had a little back and forth in the comments that did nothing to change my opinion.

The fact is that the free stroke force of the Mavens is higher than other brakes. Dale is correct here. Rather than this being a "design decision" from SRAM (as Dale stated) this relates to the seal material and its resistance to heat and general degradation (as far as I understand).

While the free stroke force adds to the overall force required to apply force to the lever, once contact has been made with the rotor, it's a very small percentage of the force required to apply force to the rotor. Beyond that, the bite and mechanical advantage of the Mavens are such that the lever force required to stop the bike is still much less than other brakes I have tried. My hands were much less tired than usual riding the Mavens and stopping and slowing down undoubtedly requires less lever force by a very noticeable margin, all through the stroke once contact with the rotor is mae.

Dale countered that most riders don't use their brakes at the highest force levels, because they aren't expert or advanced riders (his theory which may have some merit) so that free stroke force would be a higher percentage of the force used. He concedes that when applying higher braking forces, the Mavens do require less force. Another big but is that Dale said in his video that he had to stop part way down a trail (for the first time in two years) after a relatively small amount of vertical. Maybe 200 feet? It seems to me that Dale is an advanced/expert rider who, by his theory, should be using the highest braking forces - where he admits Mavens require less lever force. So why then did he need to stop and rest his hands?

Obviously this doesn't add up but Dale has succeeded in getting many comments praising his honesty for saying things that others wouldn't say. I didn't say those things because they aren't true. When I back to backed a set of high functioning Codes with the Mavens, it literally felt like I had no brakes at first. These were in low force braking situations at the top of a trail where it was low angled but a little technical. I was just trying to feather the brakes to slow down a little and when I applied the force the Mavens would require, the bike didn't even slow down. Obviously this isn't a slight difference and this is where Dale suggests the problem with the Mavens would be at its worst.

So there are two possibilities here the way I see it. Either Dale had some sort of set up issue or this was a calculation to get lots of attention for his channel. I don't know Dale and he seems like an earnest guy with a lot of good information to share, so while I hope the explanation is the former, the title of his video, SRAM's "big red disappointment" makes me believe it's the latter.

The irony is that I identified an issue with the set of brakes I have been using (a rear only wandering bit point) that to my knowledge only one other media outlet identified. SRAM does not buy advertising from us but even if they did, I would have made the same comments. Which suggests that if I had found the Mavens wanting in some other way, I would have made those opinions known.

It's a strange world when you get praised for your honesty by (in my humble opinion) providing information that is not accurate.

Reply

[email protected]

1 month, 3 weeks ago

Cam great thoughtful response. Not sure I have the need for extra stopping power, but have been intrigued with the Mavens. Have read many reviews and no other review drew the same conclusion - re lever force.

Appreciate taking the time to explain.

I suppose given your response, although the Mavens do offer more stopping power they are more then just about sheer power. Given what you have said, seems to me that with tuning of the contact point and reach one could reduce the dead stroke, get the brakes to contact in a sweet spot and have more power on tap with less effort to achieve better braking performance.

Reply

Cam McRae

1 month, 3 weeks ago

Thanks Hafez.

I'm not sure tuning the bit point would have much impact on what Dale is suggesting though because, while that force is only noticeable before rotor contact, it still exerts itself after contact is made. In fact it may increase some as you push the seals deeper into the stroke. My impression is that it would be like extending an elastic further because the seals want to return to their starting position. I guess there could be some advantage to a shorter dead stroke for fatigue but it seems to me this would be negligible. Worth a try though!

Reply

Shinook

1 month, 3 weeks ago

Cam I wish I could like this 100 times. Dales review doesn't reflect my experience at all and I think his conclusion that the deadstroke force is responsible for his hand pain is the height of absurdity.

I don't think it is intentional. I have followed him for a long time now and like most of his content, but I think a lot of riders subconsciously or consciously fall into biases and draw conclusions about things because they "poisoned the well" with other reviews. It's further possible to be honest and still be wrong, dishonesty is an intentional decision to mislead, which I don't think was his intent.

I have chronic hand problems and have for years. I've found brakes can influence this heavily depending on various factors: lever geometry/ergonomics, power delivery/rampup, overall power, fade, deadstroke, lever position, and resistance when the pads engage to name a few. What is barely part of the discussion is the resistance in the deadstroke. It can be a problem, but the force required to pull through it in the Mavens is negligibly higher than most brakes I've tried and I don't feel the fatigue often associated with it, which is more of a sore muscular feeling than a "I have to stop because my hands are on fire" feeling, which is a nerve problem. People who don't spend time making tweaks and adjustments to their brakes or lack the intuition to stop and ask "why?" will reach the wrong or, in this case, poisoned opinion. My feeling is that he read the reviews talking about increased resistance and just assumed that was the cause, not considering the fact that every brake on the market will require more force than that once the pads engage and that's' where most people spend their braking force. If the tiny amount of deadforce resistance on these brakes causes you a problem then I would be shocked you could brake at all with 95% of the brakes on the market once the pads engage.

My feeling is that it is either an ergonomic problem or the power ramp up is too severe for such a light rider and he didn't tweak pads or the contact point to try and see if it helped. If you are forced into a stronger bracing position due to more powerful brakes, that can be a big contributor to brake related hand pain as well and I could easily see how a lighter rider would fall into this problem with Mavens.

It's also worth pointing out his most recent point of reference are the Intend Trinity brakes, which have some of the lightest pull on the market even when the pads engage. It's not really fair to compare them when the Intends are made in batches of ~30, cost twice as much, and are handmade in Germany. It's more that the Trinity and Trickstuff brakes have such a remarkably light pull, less that the Mavens have an excessive one.

The sad thing is people are latching onto his review like its fact without questioning it, which is a shame. I think in part this is due to biases against SRAM, which has had a rough history with brakes, and people tend to assume brands never improve. I've had people tell me not to buy Manitou because they had problems over 20 years ago. Some of this just comes down to people wanting to find a reason to hate on them and latch onto it, if the were branded Shimano people would have a different tone.

These brakes have objective flaws. They aren't perfect, but they are really good especially for a high production brake and it is a shame people are latching onto this singular review and treating it like gospel when it is so flawed.

Reply

Cam McRae

1 month, 2 weeks ago

Very well said Shinook. I hope you are correct about Dale’s motivation but the attention economy has left me a little jaded. And it’s clear his impressions, intentionally disingenuous or not, have driven a lot of attention. I also understand why his audience is receptive to what they perceive as his honesty, simply because his opinion is contrary to other media outlets, some of which have a less than stellar reputation.

You also bring up some excellent points that may indeed suggest his conclusions are not intentionally misleading. Again, I hope that is the case

It would be interesting to do some empirical testing (ideally in an independent lab) to determine how much force at the lever is required for a pre-determined amount of pressure at the rotor to provide some untainted data for several different brakes.

In the age of influencers, unscrupulous media outlets, anonymous reviewers in coffee shops and sponsored athletes, it is truly difficult to know who to believe.

Reply

DancingWithMyself

1 month, 2 weeks ago

Very well said. Agree so much I felt compelled to say so in addition to an upvote.

Although it doesn't really do anything for me, I suppose I can understand a preference for the feel of really light lever action to the point of pad contact. But I struggle mightily with the idea that it meaningfully reduces hand fatigue. I just defies common sense.

Every time I see or hear someone laud how easy it is to pull the lever to the pad contact point, I think of the automated tailgates getting spec'd on trucks these days. If you can't manage to let the tailgate up and down by yourself, how in the world are you going to be able to make use of the bed?

Also: get off my lawn!

Reply

Cam McRae

1 month, 2 weeks ago

When I was first working in bike shops in the mid 80s, the road brakes preferred by most of us were from Campagnolo and Modolo. One thing they shared, particularly the higher end models when they were well maintained, was strong return action. This was the result of return springs rather than piston seals retracting obviously but the positive feel was satisfying and consistent while having little impact on braking power (these were also the most powerful brakes).

I still like that feel I have to say. A commonality of cheap brakes is a vague feeling at the lever that is sort of mushy and unsatisfying. I do like the light feel of Hayes Dominions because it's also quite positive thanks to reduced friction, but I also appreciate the firm feel and positive return of the Mavens, which seems to have no impact on hand fatigue (except for those who may benefit from making that case).

Reply

Ripbro

2 months ago

Can't say I a huge fan of the looks of the caliper, it looks like a prototype brake from the 90s

Is the lever feel as light at dominions? Glad to hear that it is lighter than codes, but am wondering where the mavens fit on the spectrum.

There doesn't seem to be a big difference between the silver and ultimates. Just some fancy bolts. I woudn't consider the bronze, with the bushing at the lever.

Hopefully the wandering bite point is just a one off, shimano can keep that feature.

Reply

Cam McRae

2 months ago

The lever feel is not as light as Dominions during the free stroke, which, it seems to me, is an indication that this relates either to the return spring in the lever or the retraction of the pistons or the combination of the two.

I appreciate Hayes’ recognition that every time you pull your lever, those forces are working against you, so they reduced them as much as possible. At the same time many riders want a solid and positive return feel. A thunk when you pull your lever and release it quickly. I think it provides a feeling of security.

The strong return likely prevents any mushy feeling when brakes are poorly maintained or even if a lever becomes damaged during a ride. I can see it both ways but in this case the mechanical advantage is so good that the return weight seems to have no impact on the force needed to get as much power as you’ll need at the tires - even with 200/180 rotors.

Reply

NotMeAtAll

1 month, 3 weeks ago

I've bought a chinese lever from a company named Ronglun. It resembles the Magura lever but beefier, all aluminium, has a swivel banjo under the lever to the hose so it can be routed parallel to the bar.

I have disassembled the lever and polished the barrel of the main piston to a mirror finish, rebuilt the system and tested.

Boy, that thing is smooth as glass. It makes brand new shimanos to feel like there is sand inside.

Reply

rusm

2 months ago

Is a bushing on the lever that big of a deal? Sure it'd be nice, but that and contact point adjustment, lever and to bolts are the only differences I'm seeing between the bronze and ultimate. Price point the bronze seems to be pretty awesome...if it has the same.power as the blingy ones.

Reply

cxfahrer

2 months ago

Bushings and stamped metal levers were ok on my Code for the first 6 months, since then they creak and are sloppy. Does not affect stopping power, but lever feel and feedback.

Reply

Cam McRae

2 months ago

I have yet to have that issue with Code levers, and certainly not after only 6 months. Which Codes? And does your bike meet the earth unexpectedly with some regularity? ;)

Reply

Shinook

2 months ago

Every lever I've ever had that rotated on bushings ended up with lever slop over time, brakes that don't rotate on bearings are a hard stop no for me after this. It's just an inevitability and I find it really annoying having the lever flopping around while riding.

Reply

rusm

2 months ago

Ok good points, I've had some bottom end codes before and haven't had that issue either. But I would definitely be annoyed if I had experienced it!

Reply

jason

2 months ago

Using putolite 2.5 weight oil on Xt brakes eliminates the wandering bite point.

Reply

Cr4w

2 months ago

These came out pretty quick once the once-size-fits-most category of rider got on 55lb ebikes and needed Clydesdale level braking. Me on my Mega still outweighs a 175lb guy on a big ebike by at least 30lbs. I've been doing pretty well until now on XTs with 220mm rotors front and rear. I can't wait to try these brakes as I've always maxxed out my brakes however possible. I look forward to lots of little people on non-ebikes suddenly not being able to live with their Code RSCs anymore (the same way they suddenly couldn't live without 38mm forks), adorbs.

Reply

Timer

2 months ago

I always thought the reason that E-motorbikes come with much bigger brakes is not weight. Just that the target customer for an e-Mtb is likely much less experienced and therefore more likely to drag his brakes down every hill. Which is more of a problem with motorbikes because they give anyone access to lots of verticality.

Reply

rojo

2 months ago

As a lightweight rider at 60kg, I have often contemplated how badly the sport caters to heavier riders.

I run 38mm Boxxer/FR1950 wheels/220mm rotors both end... there are few stronger components available. Yet I don't find any of them overly stiff.

I found that Zeb performs better than Lyrik, with no downsides...

Even at my featherweight I appreciate that components like these are getting tougher.

Reply

Peter Appleton

2 months ago

i hope Eddie Van Halen sues

Reply

XXX_er

2 months ago

Isn't it great when a product comes with a pre-scratched/ pre stressed finish

Gotta wonder what Eddie was thinking when he painted that guitar

Reply

Kyle Smith

2 months ago

Looks like you're not the only one that has experienced a rear wandering bite point. Travis over at the Radavist had a similar experience.

https://theradavist.com/promising-but-inconclusive-a-sram-maven-disc-brake-first-ride-review/

Reply

Timer

2 months ago

Looks like they finally caught up with Shimano?

Reply

Cam McRae

2 months ago

We talked. He had his Mavens for more time and had more opportunity to dig deeper. I have yet to re-bleed and re-massage the pistons so we’ll have to see how that pans out after more than just a few rides.

I only noticed mine after the ride in the parking lot as well so my issue was less significant than his. I did manage some long descents though and in use the brakes were fine which is also a little puzzling.

That used to be a Hayes thing on long descents. You’d stop to regroup and your lever would go to the bar. My issue was after everything had cooled down but it disappeared once the bike was hanging in storage.

One thing is certain; SRAM is taking the issue, which seems isolated to Travis and I, very seriously.

Reply

jonkranked

2 months ago

good to know SRAM has already acknowledged it and is taking it seriously. will you share any updates you hear from them?

Reply

Cam McRae

2 months ago

These will warrant some updates and I will keep you apprised of relevant developments. One of the reasons for the serious response was that apparently, SRAM hadn't seen this issue in early production examples.

Reply

Shinook

2 months ago

Did ambient temp have an effect? It hasn't been cold enough here yet for me to try when it is below freezing, which is when I usually have problems with Shimano brakes.

Reply

jonkranked

2 months ago

i think the cold weather performance issue is more of a mineral oil thing rather than any particular brand of brakes

Shinook

2 months ago

@jonkranked - I only ever had that issue with Shimano, my MT7s never had any issues in the cold, at least that I could reproduce. I haven't tried TRP or other mineral oil brakes to compare.

Cam McRae

2 months ago

I haven't been able to make a temperature association yet but it was certainly above zero when I experienced the issue.

jonkranked

2 months ago

thanks, that's good to know. i would assume any potential issues would be covered by warranty. didn't deter me from ordering.

Reply

Shinook

2 months ago

I've been having this same problem. I probably bled them 6 times and worked the pistons in/out numerous times. I'll probably end up rebuilding the caliper soon because I'm worried I may have fubared the seals doing it so much.

I was able to significantly reduce it using two rotors pushed together and shoved into the caliper, then working the pistons out and pulling the levers HARD. I tried this several times prior and had no luck, it wasn't until I let the lever out and really pulled on it that it seemed to largely go away.

It's a risky procedure, though, because the pistons look really close to falling out and I'm sure pushing one back in too hard would pop another one out. I also couldn't find it in SRAMs service manuals despite several others saying it is there. IMO this is not a great process and if it is necessary, should have a tool involved rather expecting people to do it properly with rotors, I expect a lot of popped out pistons as a result of this process. A bleed block like the Dominions that allows you to press them out safely would be a really good option.

Either way, it largely solved or reduced it for me. My ride today with them was really bad, I had to pump the rear just to get enough power to slow down and I had to plan it out way in advance. I got home and fuddled with it, with no luck until I tried the above and put more pressure onto the lever.

When they work, great brakes though. The presentation in the box is really nice and I am glad they put it all in one package.

Reply

DancingWithMyself

2 months ago

For me personally, arguing with brake pistons is a distant first on my list of most annoying bike maintenance tasks. And I would guess it’s even more of a PITA on these calipers given the limited access from the top of the caliper.

I’m never worked in a shop, but it seems like empathetic shop owners should consider giving a day off to any mechanics who were around for some of SRAM’s earlier efforts at brakes. This has to be triggering for them.

And I’m far from a SRAM hater. I run codes with MTX pads and might be intrigued by these, but it’s a hard, hard “no”until I am 110% sure this issue is fixed.

Reply

Shinook

2 months ago

There is only one piston that is harder to access IMO, it's the rearmost piston closest to where the caliper bolts, it's slightly covered, so it's harder to reach to press in place. It's not difficult, but it's harder than it would be with access to the top. Either way, I don't see it being a bit deal.

Reply

JT

2 months ago

I blabbed my thoughts over there, but I'll provide a Cliff's version here. Sounds like a fluid restriction in the system. It could be the volume of fluid returning from the cal is too much to move through the banjo fitting, insert, or both. That hydrolock can cause enough of a pressure change at the primary seal for the fluid to temporarily gas out as it corrects to the vacuum created on lever release. Once the fluid gasses out, you get a longer lever throw, and once the fluid from the caliper is able to return the throw should return to near normal. Having it happen on the rear (mostly) is reasonable since the it sees a lot more action than the front. I've seen it happen on other brakes, MTB and moto. Massaging the pistons gets the seals properly lubricated to deliver the proper amount of piston slip, so ultimately shouldn't be more than a one n done scenario on initial set up (or after overhauling calipers). Both Hayes & SRAM had this as a corrective action for brakes in their history, and it helps with Shimano brakes, especially any of their brakes using ceramic caliper pistons.

(Sorry, that was decidedly NOT a Cliff's version but there was a lotta ground to cover)

Reply

Shinook

2 months ago

The issue is that it goes from a longer throw to shorter throw. When the bike sits idle and you pull the lever, it'll come to the bar, then the second time you pull it, it'll be a shorter stroke. The second pull is what they should feel like. Mine did this out of the box. If you watch carefully, you can see the pistons aren't retracting to their normal idle position by the time you do the second lever pull.

My observation is that the problem is related to pistons retracting too far. If you insert a thinner rotor then use a larger rotor, the problem goes away. It also doesn't reveal itself with the bleed block in place, just when the pistons are slightly extended. My front does it slightly, but not nearly as bad and I suspect the reason being that it's easier to get a stronger pull out of the front than the rear.

For whatever reason, working the pistons out and putting them under high pressure like I mentioned above seems to fix the problem, at least in the stand. We'll see if it holds up to riding but that came recommended by shops and several reviewers, although it's not in the SRAM documentation for whatever reason. Being blunt, it seems like a janky process that should've been done at the factory especially considering the risk of pistons popping out.

Reply

JT

2 months ago

Interesting, that seems opposite what Travis was experiencing. Still, a fluid restriction could account for that as well. Fire in a theater and all. It'll be interesting to see what the communications (and maybe replacement parts) are like regarding it down the line.

Reply

Shinook

2 months ago

When I read it, it sounded like the same issue, the bite point moved further out (away from the bars). Maybe I misunderstood, either way, that's what I had until I did the procedure above (even after it seems like it's slightly there, more riding will tell).

Either way, this is ultimately my biggest issue with SRAM as a brand. How do I get answers on this? Through my LBS? Maybe they know, maybe they don't and won't deal with it. The last time I had SRAM brake problems (Guides), the shop wanted to charge me $25/side for the warranty process then $80 to bleed and install them, on brakes that were faulty from the start. I'd much rather deal directly with the brand rather than have to deal with a shop charging me to warranty something that should've worked in the first place. My shop now is great or I wouldn't have gotten them from them, but I would really just prefer to deal directly rather than risk whatever gatekeeping is involved in getting stuff fixed.

Reply

JT

2 months ago

I'll have to give it a 4th read through. Maybe I misread, def a possibility being a human and all. I hear you about the warranty side of things. Coming from bike into moto industries, it was wild that dealers were getting paid labor (and at decent rates) to handle warranty repairs. The customer is only down time. The bike shop I worked at rarely if ever charged for warranty work, but I'm pretty sure the owner was smart enough to keep track of it and write it off on taxes. Bike industry has a long way to go on that regard. If these calipers are already having piston slip/retraction issues that doesn't bode terribly well for how they'll be working after a year or two.

EDIT: I erred in reading comprehension. He had the lever pumping up as well.

Pete Roggeman

2 months ago

What you're talking about here is an issue I've been discussing with a few different people lately. Your LBS is the front lines (for you) with a warranty, but how they're able to deal with your claim sometimes relies on what the brand in question has done to support shops - ie. do they provide credit or some kind of compensation to the shop to deal with the warranty. In the case you mention, maybe not. Obviously there's often relationship issues at play (shop to customer, shop to brand) but what's been interesting to me is hearing about the discrepancies in how various brands (and/or distributors) account for the efforts a shop has to undertake to help with warranty claims.

This is becoming a bigger issue with e-bikes since some of the problems they face are more time consuming to deal with (diagnosing the problem can take 1-2 hours, THEN components may need to be removed, returned, re-installed, etc).

Anyway, it's something we're keeping an eye on, but your comment resonated with me as I've had this conversation lately with several mechanics and shop owners.

Shinook

2 months ago

@Pete: It's a tricky situation, no doubt, but since I do almost all my own work (aside from suspension rebuilds), it's frustrating when a brand has no avenue for directly interacting with customers when issues like this arise.

The obvious situation applies. The shop needs to make money off labor, filing warranty claims has a cost, but as a consumer it is annoying to buy a product, then have to pay to warranty it due to a defect. The shops often (rightfully so) don't trust people to do the work right and to avoid a situation where the customer screws it up, they insist on doing the install. It's difficult because a lot of people aren't really capable of doing this sort of thing, but for those that are, it's irritating to be forced to pay more to fix a faulty product that was faulty from the start. My now $xyz product is $xyz plus the cost of labor and filing the claim.

You also have to add in the shop politics/social element, as well. Some of them will insist on trying to rebleed and do a bunch of work that was already done, then charge for that plus the above. Now I'm paying for labor to do something I already did, only to pay for the warranty claim, then have it done again, all for something I can do myself due to a product that failed due to no fault of my own. OTOH, SRAM likely wants the middleman to cut down on claims due to owner negligence or error. There are also bike shops that just suck, I had one tell me Guide pistons didn't stick and refuse to help with the issue despite it being widespread and well known. Another told a friend his fork being sucked down into 30% of its travel with no weight on the bike was for 'top out protection' (clogged equalization port). I have numerous stories along these lines where shops refused to fix things even if the customer was willing to pay for it.

Meanwhile, the brand wants to avoid faulty or erroneous claims due to operator error or falsehoods, so they defer to shops (who, IME, are equally likely to do the same thing) to act as the middleman. This results in the customer having to potentially pay for services they may not need or deal with middlemen who might complicate what should be a simple process. The Guide example is one I reference a lot because it's cut and dry, sticking pistons were a widespread, well known and recognized issue, I shouldn't have to pay $130+ to have them warrantied or call around to find a shop who knows its a problem. Dealing with the brand directly makes this a lot easier and more straightforward for people who don't depend on bike shops.

I don't fault them entirely. 95% of society is full of morons or aholes and dealing with the general public is VERY irritating. I've known folks over the years who worked in these roles and the type of thing they have to deal with would probably make me push for the same model, but it doesn't relieve how irritating it is as a consumer. I also understand this is a cascading problem requiring staffing, ticketing systems, etc and it's not trivial, but brands like SRAM and Shimano should have some facilities for dealing with customers. I say that fully understanding their main emphasis has and always will be OEMs, which I think is also part of the reason things are the way they are.

These brakes were sortof an exception for me, I wrote off SRAM years ago for this reason after a negative warranty experience that was clearly a manufacturing fault that stuck me with the bill. It was frustrating trying to deal with having the shop accurately explain the issue, then be denied because...reasons? I have no idea what the shop told them or if it was accurately represented, but it was a clear fault in basically a new component. Effectively every other brand I've dealt with in the past few years all allows for direct customer support and I have, as much as is feasible, cut out brands that don't.

(Sorry for the tome, this is a soapbox for me)

GB

2 months ago

Lol. How powerful brakes are is defined by one parameter. And Sram now acknowledge this fact .

The ratio of the lever piston to the combined surface area of the caliper pistons .

Trick stuff was the winner in this category. I have not done the research but these are either as powerful or perhaps more powerful.

I want powerful brakes . These are powerful brakes . Realy modulation is in your hands more than the equipment. Shimano brakes are quick to bring in the power . Not a problem when you learn to adjust .

Few questions.

How much for brake pads ? New shape ? Which limits availability.

Can I bleed these with a syringe and a rubber tube shoved onto a sram bleed barb .? Whole new bleed kit needed ?

I don't think the excessive weight is nessary. I'm certain the weight will slowly reduce each year as a selling feature.

Yes if you change pads especially if you change compounds . Sand the rotors to remove all the brake compound embedded into the rotor . Works for me .

I would just buy the calipers and use Shimano levers . ShiSramo brakes .

Cam thank you for a proper write up and test of the brakes .

Reply

Mammal

2 months ago

I doubt it, regarding reducing weight over time. Increased mass is one of the best ways to manage buildup of caliper heat.

Reply

BarryW

2 months ago

It's an interesting question. Shimano solves that by making the rotors bleed heat much more effectively than any SRAM product.

Now SRAM is making the caliper beefier to manage heat.

Hmm. Different ways to solve the same issue. Myself I'm running ceramic pads that tend to not heat the caliper and fluid as much, but might put all that into the rotor, so I'm running Ice-Tec rotors and super happy with the heat management.

It seems motorsport is alway on the losing heat through the rotor program rather than making a larger heat sink on the caliper.

The one huge advantage to a more powerful brake like these is allowing you to downsize the rotor. Seems like a good way to keep them out of harms way.

Reply

olaa

2 months ago

Regarding using Ice-Tec rotors: Got G4 ultimates on a bike I recently bought with 200 mm Centerline rotors. They overheated and really did not feel all that good. Changed to same size Ice-Tec rotors, and now the brakes are actually ok. Not great, but ok.

Reply

Cam McRae

2 months ago

That is an interesting point, but not what SRAM suggests is their entire goal by increasing the thermal mass. More cooling may not be what they are after entirely. Here is in their words:

Built for greater thermal mass, they take longer to heat up, keep excess heat at bay, yet retain optimal heat so as to not cool down too fast. When the caliper avoids the peaks and valleys of hot and cold, consistency of performance reaches totally new levels.

It's possible that more cooling at the rotor would be counterproductive but I'd need to talk to one of the engineers to confirm this, which I could work on for a follow up article once the dust settles a little.

Reply

Cooper Quinn

2 months ago

Goddammit I wrote out a big reply here that got erased before I could post it somehow. Try #2.

Brakes turn kinetic energy into heat, which you have to manage and ultimately dispose of.

Things like Freeza rotors build heat quickly because they're light, and are designed to dump that heat quickly.

Mavens have a large caliper mass for 1) stiffness and 2) thermal stability. Yes, they'll still get hot and stay hot longer, but that's kinda the point. It keeps friction compounds (pads) in their optimal operating temperature window leading to increased consistency and feel on the trail.

Motorsport comparisons aren't entirely fair given the orders of magnitude changes in mass ratios you're dealing with, considerations for sprung/unsprung weight, center of mass, and the very high operating temperatures. And speeds. But ultimately there are many of the same things at play, just very different design parameters and requirements.

Reply

BarryW

2 months ago

That would be an interesting question to pose to the SRAM engineers. Not saying they are wrong because they make great products but I am curious about the reasoning.

The bit you quoted above is interesting and I do know that in motorsport there are some incredibly cool systems to actually raise the temp on the braking system to keep it at the ideal. Although I'm fairly certain that is for carbon rotors where they NEED significant temp to operate effectively.

@Cooper, good points about how motorsport is different, and how keeping within the optimal temp can aid consistency on trail.

Reply

ohio

2 months ago

Re: the weight... if it allows you to downsize a rotor (or keep the 200mm rather than upsizing to 220mm) that erases about 2/3 of the weight diff between Mavens and Codes. Also agree with @Mammal that you shouldn't expect weights to change year to year.

I also like the strongest brakes I can get (and afford). Currently on Dominions A4s with MTX reds and even those are not as much as I'd like. Will give these a season to let others shake out the gremlins, and then if all good likely make the switch.

Reply

BarryW

2 months ago

Give the MTX Golds a try, instead of up sizing my rear rotor to 203 my 180 is plenty of brake with the Golds.

Only costs a set of pads...

Reply

Pete Roggeman

2 months ago

Pad replacement cost is a great question but I'd have to imagine they're similar to current pads, otherwise they'd be touting a compound change or other advancement. Availability also relevant but not for long.

Reply

Cam McRae

2 months ago

27 USD a pair for either organic or sintered.

MTX posted that they are working on this already and should have some by summer, and other aftermarket providers are undoubtedly doing the same.

It'll be interesting to see how performance stands up as the pads wear. Early Codes didn't respond well when the pad material got thin but more recent ones are better able to deal with using the last half of the pad material, which was previously a Shimano advantage in my experience.

Reply

Shinook

2 months ago

Agreed, all the SRAM brakes I've had over the years started to deteriorate in the last 20% or so of pad life. I actually didn't mind it because it prevented me from running the pads longer than I should, whereas Shimano I swear you could run down to the backing plate and not notice much of a difference

Reply

rojo

2 months ago

F1 drivers don't have very powerful brakes. Power assistance is banned so they have to press on the brake pedal with all their might (and do strength training accordingly). That said the calipers are optimised to be extremely stiff so they can use the maximum mechanical advantage possible without too much pedal displacement, so your analogy between this and an F1 braking system is fair.

Reply

danithemechanic

2 months ago

Suddenly i just got it, all we have to do is pair the calipers with these bad boys:

Resto mod for the win!

Reply

Cr4w

2 months ago

This comment has been removed.

Duncan Wright

2 months ago

So on the one hand, it's cool to see SRAM finally come up with a brake that stands up to the competition, but on the other...holy smokes those are not nice to look at.

Reply

Mammal

2 months ago

I don't mind them. I like the brutal look.

Reply

Shoreboy

2 months ago

The main thing I like about these is the Van Maven paint job on the calipers. That and the move to mineral oil over DOT. I've never felt the need for this much power. Riding Saints or XT 4-pot with 203mm rotor front and 180mm rear has always been plenty for me, though I do have to admit i'm not in the Clydesdale category of rider.

Reply

Cam McRae

2 months ago

I wouldn’t have said I needed more braking power either actually. And then I rode the Hope E4s and realized how advantageous it was to get the power you need with less force at the lever.

These take that a level up and the difference between the Hopes and the Mavens (which I’m also running with 200/180 rotors) marks a similarly significant improvement on the trail. I can get enough power in most situations with codes and big rotors, but with these I get that power while putting less stress on the muscles in my hands which leads to more control (better modulation) and less fatigue, which impacts more than just braking

Obviously this is terrain related and long steep trails are what I enjoy most.

(I weigh 165 lbs so I’d need to do some bulking to be a clyde as well.)

Reply

jonkranked

2 months ago

i'm currently 230lbs (packed on some extra weight due to lack of exercise from a ruptured tendon in my right calf back in the fall). I'm currently on dominion a4s and while i have no complaints on them, pulled the trigger on these to give them a shot. the launch kit they are offering is a pretty good value IMO.

Reply

FlipSide

2 months ago

Same here. The value of that launch kit was too good to pass up...and now is a good time to move on from the stock Guide RSC my Spartan.

I hope such significant bargains for early adopters will become a trend.

Reply

Shinook

2 months ago

Yea the value of that launch kit is really good.

I doubt we'll see it become a regular process though. For users of SRAM and Shimano brakes, I think these are something entirely new and they rightfully figured people were going to go buy them, throw them on whatever rotors or adapters they had, then have issues. The bleed tools in particular were a good inclusion, I could see a lot of people complaining about the lack of availability and avoid buying them as a result, now they have thousands of bleed kits in circulation among shops and friends that it would be less of an issue. The adapters similarly would reduce confusion and frustration, since I don't think these would fit on many adapters. They probably figure the kit is a loss leader to drive circulation of tooling and awareness of setting up the brakes, as well as the brakes themselves, in the long run.

It's remarkably generous given the way they usually work as a brand, but at the same time, it's smart to do it in limited numbers and that flashy caliper stands out, further driving awareness. I had 3 people ask me about them on my first ride, it was the first thing they noticed on my bike. That wacky obnoxious color scheme serves a purpose, you are a rolling billboard for the brakes. There's a reason you can only get the kit in that color scheme.

Smart on their part, but not something I'd expect to see a lot of.

Reply

93EXCivic

2 months ago

Out of curiousity how do these compare to MT7s? Those are my current favorites,

Reply

Cam McRae

2 months ago

It's been too long since I've been on a set of Maguras to provide any valuable impressions I'm afraid.

Reply

Shinook

2 months ago

I briefly (~1mo) had MT7s on my bike before putting these on, so I can compare a little bit.

The power on the Mavens is a lot stronger, at least it comes on faster and more progressive with less lever pull required. The lever pull has more resistance as you get into the stroke on the Mavens but you get more power for the pull, if that makes sense. The MT7s have a slightly gentler feel on the pull, but you have to pull them further in to get the same power out of them and it builds slower / more linearly (some may call this modulation). The Mavens feel a lot stronger and more powerful, you can also run the lever closer to the bars and achieve the same power.

I never had alignment or bleed issues with MT7s, some seem to, but I found them easy to work on.

If I were running an aggressive trailbike, the MT7s would probably be a better choice. They had plenty of power, but not as much as the Mavens IMO. I liked the lever feel of the MT7s, but there were a few times going between more powerful brakes I'd pull the lever and not get as much power as I had hoped compared to brakes like Kahas and Mavens. This really only manifest itself on tighter sections where I'd need to come off something, get the bike slowed down quickly, then do another feature. It was entirely doable with the MT7s, but going between newer and more powerful brakes, the power ramp up difference is really noticeable. I also couldn't get away with 180mm rotors on the MT7s, the Mavens make me consider going down to 180mm in the rear.

The MT7s were more consistent, see the note on wandering bite point above, but so far my Mavens have been fairly consistent after following the piston reset/seat/whatever procedure.

I really liked the MT7s and could probably adapt to them fine over time. The jury is still out on the Mavens, but the power and lever feel difference is pretty clear.

220lb rider, heavy Starling, professional bumbler. Lighter riders may have a different experience. Only ran "performance" pads, never tried the "race" pads.

Reply

Vincent66

2 months ago

Thank for your experience.

I was a big MT5 fan for 8 years, and after breaking several levers, I decided to switch to Hope T4V4.

I was using MT5 with HC i finger levers and several sets of pads from different brands. I have never been disapointed. I never found them hard to bleed.

I'm really happy with my switch to hope ; I have no intention to move, but I'm curious how they would compare to mavens.

Reply

Shinook

2 months ago

I probably should have mentioned I used the HC-W lever on the MT7s. I never tried the others. I only did it this way because it was so cheap and I got a deal on them ~$350USD for rotors and brakes.

I agree re: bleeding. I'm not sure where difficulty comes from on that, but a lot of people made it sound hard to bleed, they were super simple. Alignment was a little trickier, but not really by much. I liked them, I just wish they had a bit stronger engagement.

The Hope Tech 4 V4 are really good, I had them on another bike for a while and the lever feel is super smooth and gentle, probably the easiest lever pull to power ratio of any brake I've used. Great power, no fading, good ergonomics and adjustments that work. The Mavens have a more "wooden" feel when the power engages and it feels more solid, they also come on a little faster and stronger. The bleed process is easier as well, I was never a fan of the Hope bleed process especially combined with DOT, I'd rather the entire system remained sealed as opposed to openly dripping and draining DOT. Minor nitpicks but they were otherwise really good and I like that they are made in the UK, especially that you can actually talk to people at Hope, that's a huge selling point (see my previous soapbox on this subject)

Reply

Skooks

2 months ago

Nice write-up Cam. Do you have to remove the wheel (or caliper) to replace the brake pads?

Reply

jonkranked

2 months ago

yes. they are not back loading.

Reply

Cam McRae

2 months ago

Jon is correct. Unlike Code pads, which load from the top, these go in and out from the bottom due to those four bolts blocking access from above.

GB - the pads will cost 27 USD a pair. Sintered and organic are the same price

I imagine it would be possible to jerry rig the bleed to a certain degree but you’ll need and a threaded fitting for the lever and a bleeding edge fitting, which is included when you buy a set of Mavens.

And Mammal is correct regarding the relationship of mass and heat management, but there are probably other solutions possible - particularly if cost isn’t a barrier. F1 calipers are made of aluminum-lithium alloy and they weigh between 1600 and 1800 grams. Considering the diffference in loads, that’s pretty light. Obviously you can get some incredible air cooling when you approach 300 km/h so that’s a factor as well.

Reply

Cooper Quinn

2 months ago

F1 brakes also operate at like 500-1200deg C so.... they get pretty warm.

Reply

rojo

2 months ago

Adding stiffness to the caliper absolutely makes sense, but I'm not sure about the claims that adding thermal mass to the caliper is of benefit to the friction performance. For an F1 car the objective is to isolate and cool the caliper from as much of the brake heat as possible to keep the piston seals and fluid at a good temperature (which have problems over 200C). At this point it is fair to point out that F1 brakes operate in an entirely different temperature window...

However, the reason why I'm a bit cynical of the marketing talk is because it is the temperature at the pad/disc interface that is important to brake Mu. This is deliberately insulated from caliper temperature (pistons are insulating for the reasons above), so in a situation where the disc has cooled, I doubt the caliper is keeping the braking surface warm. Add to this that by the time you have climbed to do your next ascent, your whole brake assembly is stone cold again regardless of how much your caliper weighs.

If you want to smooth out the peaks and troughs of temperature during a descent then adding thickness to the disc or mass to the pads seems like a better candidate.

Reply

Tjaard Breeuwer

1 month, 3 weeks ago

Agreed! There is no benefit in keeping the fluid warm, which is what the bigger calliper is doing.

Thicker rotors and bigger backing plates for the pads would be good. Thicker rotors have the added advantage of being less prone to bending.

Reply

Glass

2 months ago

How do these brakes compare to the Hope tech 4 V4, Shimano Saints and Shigura setup? I've currently switched to a mullet setup and find 203mm discs not providing enough power.

Reply

Cam McRae

2 months ago

This quote from my article is apples to apples because I have 200/180 rotors with both bikes - but they are the E4s. I haven't ridden recent Saints etc.

"I'm very happy with my Hope Tech 4 E4s so they aren't going anywhere, (the Mavens generate significantly more power in my estimation while the Hopes have finer modulation)."

Reply

Steven Hambleton

2 months ago

So DB8 remain the only SRAM brake that doesn't use Bleeding Edge?

Reply

Tjaard Breeuwer

1 month, 3 weeks ago

I am interested in these, as even at 180 lbs, I have found my left (front brake) hand gets tired on long descents. Running Code Ultimate with 200mm HS2 rotors f/r.

But, I live in the Midwest, so most of my descents are NOT long, so I have not wanted to upsize to 220 in the front, because by the time that giant radiator is up to a good operating temp, I’m already at the bottom of any trail here at home.

Combining these 2 factors is why I run Galfer Pro pads: they bite even when cool, and heat up quickly, and have a lot of power.

So, a more powerful brake would be nice, at least in front.

I do wonder if that would mean I’d need to switch to a180mm rotor in the rear? If the 200 would just lock up to easily? But then I’d worry that it would heat up to much on big mountain descents.

So maybe the ideal set up would be a less grabby pad in the rear, and 200mm rotors both ends?

But that would be a pain. Keeping spares of 2 types of pad on hand (in addition to the Code pads for my kids bikes), and remembering which pads went where, and which rotors were used with metallic vs organic pads…

Maybe I buy 2 Mavens, and put 1 each on front of both my and my oldest kid (who weighs almost as much as me)s bike.

Reply

Cam McRae

1 month, 3 weeks ago

Sounds like an interesting experiment. Please let us know how it works out if you try it.

Reply

GB

2 months ago

I read an interesting anecdote on MBA.

Sram suggest that one needs to massage the pistons and keep them lubed .

Sram knows about the sticky piston issise and I believe that is the cause of the lack of consistent brake feel. Similar but I'm not certain it's the same as Shimanos Wandering bite point .

It's interesting to note it's always the rear caliper . I have good luck with my bleeding process on my Shimano rear brake . No more rear Wandering brake bite point . I make a concerted effort to pull air bubbles out of the caliper . That appears to fix the issue .

Every 4 pot caliper I have used was annoying. I would look at the 4 pistons and observe they are all resting at different positions.

My local bike mechanic explains how easy it is to pull out the pistons and re lube the pistons and seals .

Personally I like to just ride my bike . I'm not investing my time rebuilding calipers just to have reliable consistent brakes . The arm chair in me engineer thinks that two sizes of pistons to apparently push in the pad with different ratios causes the pads to be at an angle when contacting the rotor . So for me 4 piston calipers with different size pistons is an unnecessary step that causes issues .

Please correct me I'm I'm wrong . On motorcycle and automobiles multiple piston calipers use the same size pistons .

In conclusion multiple piston calipers look cool. But cause many issues .

You can have the exact same level of power with just 2 pistons .

And esthetically these are the ugliest calipers I have ever seen!

Good try Sram .looks like you need to do some changes. Or pretend nothing is wrong lol.

Reply

Please log in to leave a comment.