First Impressions

Forge+Bond Shift AM Wheels

Backstory

Utah based CSS Composites quietly snuck a new way of manufacturing carbon fiber rims into the world sometime back in 2020. Dubbed FusionFiber, this new process involved taking nylon-impregnated carbon fiber and laying it up into rims via a proprietary process using heat and pressure, but no resins or curing agents like traditional carbon fiber layups. It's a thermoplastic, but done with some secret technique that CSS doesn't want to spill the beans about. The short version is that this highly automated process uses less material, involves less environmentally toxic material, cures rapidly, arrives at its final shape with no sanding or extra finishing steps, and is a more flexible, less brittle final product than traditional carbon fiber rims. FusionFiber first debuted on Revel wheels, followed by Chris King.

In addition to claiming lower toxicity and less waste during manufacturing, FusionFiber is also recyclable. Sort of. A mangled rim can't get melted down and turned back into another new rim, but it can get chopped up and turned into something a little smaller, like tire levers. Or, as co-founder Joe Stanish proudly showed me at Sea Otter a couple years back, an assault rifle barrel shroud with in-molded picatinny rails. Basically, FusionFiber can get repurposed into smaller, less structurally critical items.

Forge+Bond, meanwhile, sprang to life last year in Gunnison, Utah. This is the bicycle wheel-shaped, public facing branch of CSS Composites. Pairing their rims with I9 hubs, Forge+Bond joined a very exclusive club alongside Enve and We Are One in offering a wheelset designed and manufactured almost entirely on this continent (Belgian Sapim spokes being the "almost" fly in the ointment here). Uncle Dave went pretty deep on the initial Forge+Bond release last year here, and also did a better job than I am likely to do of discussing the recyclability angle.

Paradigm Shift

US made is something we can applaud. Yet another $2,500 carbon fiber wheelset, well, that's a little harder to get jazzed about. This is where we roll around to the subject at hand: the very recently released Forge+Bond Shift wheels. A new line of wheels, featuring the same rims as the wheels that debuted last year, but with F+B branded Bitex hubs, and a retail price of, drumroll please: 1250 USD per set. For the purposes of direct comparison, the F+B Shift AM wheels here undercut WAO's Revolution Union wheelset (admittedly with an I9 1/1 hubset) by 150 USD, and similarly outprice Enve's AM30 by the same amount.

Yes, you can absolutely find carbon fiber wheelsets for less. But they won't be made on this continent. And yes, you can find aluminum wheelsets with similar weight and width and shape and maybe even ride quality for even less still, but at that point we are no longer really engaging in apples to apples comparison.

As is de rigueur these days, the F+B AM rim is subtly profiled. Aesthetics or performance?

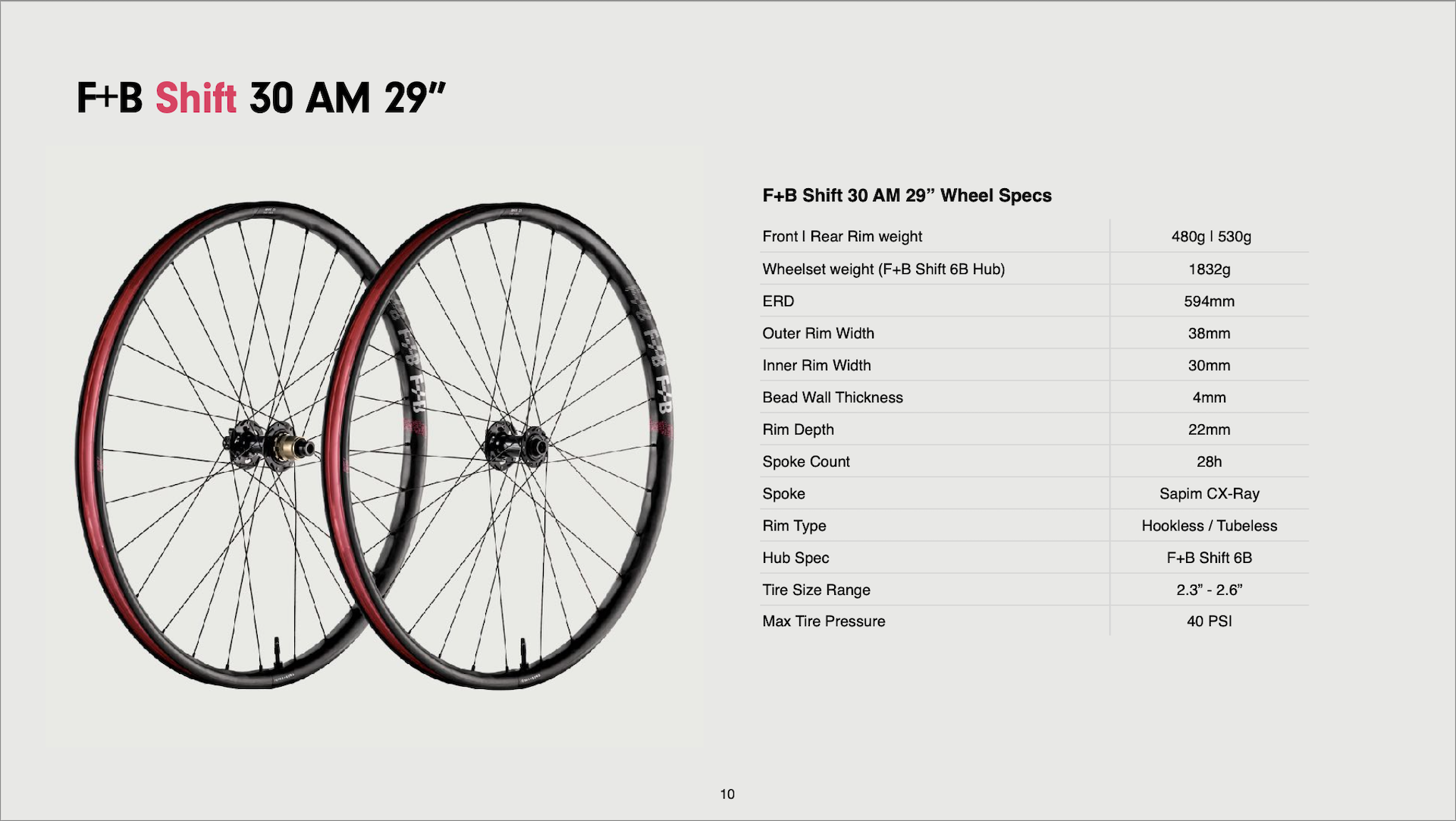

There are three models of wheel in the Shift family: the Shift XC, the Shift AM, and the Shift EM. The Shift XC features 25mm inner width, 28-spoke, 385-gram rims front and rear in a 1,600-gram wheelset. The AMs have a 30mm inner width, 28-spoke rims, with the front rim featuring a lighter construction than the rear, weighing 480 grams and 530 grams respectively, in a 1,823-gram wheelset. The EMs are enduro-oriented, and feature the 530-gram rims front and rear, with option for 32-spoke builds, and a slightly more chonky 1920-gram full set weight. And in each case, you can get any rim diameter you want so long as it's 29". Okay, fine; so long as it is 594mm ERD, just in case someone wants to get pedantic in the comments.

Aside from being exclusively 29 inches, the Shift wheels are also only available in Boost spacing and 6-bolt rotor configurations. You can choose between SRAM XD and Shimano Microspline drivers, but that's about the extent of it.

All Shift wheels come with 60-day no questions asked return policy, lifetime warranty, and no rider weight limit. To clarify, the lifetime warranty is defined as: "In the event you crack one of our rims during normal intended use, we’ll replace it for free. We process all warranty claims through our production lab in Utah, that’s how we reclaim our FUSIONFIBER® material and create something new from it." The warranty does not cover labour, nor does it cover running your own wheels over with your car, but there is a reduced-cost crash replacement program for scenarios like that. Not mentioned in any of this - the hubs.

The AM29 deets. These are the wheels F+B sent...

XC29, for the lightweight-ish experience.

And EM29 for the kids who break their toys.

The Devil In The Details

So, purchasing F+B AM rims by themselves would set you back $850 US per pair. If you were going to have your local wheelbuilder twist you up a set of these, you'd be looking at another $100 for spokes, at least, and $100-200 labor. You would still need hubs, and valve stems, and rim tape. From a value proposition standpoint, these Shift wheels look pretty good. They come with some modern, insert-friendly, hi-volume valve stems, sturdy tubeless-ready rim tape, and this pair mounted up very easily with a floor pump and a pair of Specialized Purgatory T7 tires.

The guts of the matter - 6 pawls, 4 bearings, steel axle.

27 teeth, and I counted 54 clicks in a rotation, so that means at any time 3 pawls are engaging, right? Or does that mean that only one pawl engages but the pawls are clocked so that they can still double up on engagement points? Gotta love it when a company signs their name on their spokes...

The Bitex hubs are sourced from Taiwan and are a relatively known quantity, although my personal experience with them is about zero. The general consensus around the interwebs is: "pretty light, inexpensive, relatively reliable." TPI cartridge bearings should be easy enough to replace with something nicer if they get crunchy, and the rear hub design - axle supported by two bearings in the hub, two in the freehub, ring ratchet in hubshell engaged by six-pawls on the freehub - is common and easily understood. I counted 54 points of engagement in a rotation, so that'd work out to somewhere around 6.6 degrees. That's tighter than a DT 36t ratchet and on par with a DT 54t, but fans of super tight engagement may find something to gripe about since they are not I9 hubs...

J-bend Sapim CX-Ray spokes span between rims and hubs; these are becoming downright ubiquitous in wheel world these days and are generally regarded as one of the more solid go-to options. I am a big fan of J-bend spokes, and am glad that F+B didn't try to do anything fancy by courting perceived straight pull bling factor while also hitting a budget target. I freely acknowledge that my bias there may be due to emotional scarring caused by some truly shitty straight pull hubs back in the dark ages. I am similarly leery of black spokes, but since those things are unavoidable these days, I just keep my mouth shut and try not think about it too much.

Do valve stems deserve their moment in the sun? Hell yes. Especially when they have insert friendly exhaust ports and little hex heads so you can slap a wrench into the end and more effectively tighten or loosen them...

And DOUBLE especially when the valve cap can double as a core removal wrench. Sweeeet...

Putting The PRE In Preview

I received these wheels very recently - the embargo just came off a couple weeks ago -and am currently ass-deep in riding an XC bike that has featherlight wheels on it. I do not want to taint that experience any more than I already have (by wearing baggy clothes and a helmet with a visor), so this is a preview. Therefore, in terms of ride characteristic, I can't speak to that just yet. Similarly, wheels with zero miles on them tend to stay true. So I can't speak to how they are holding up, either. Yet. These wheels will spend the summer getting long-termed on a more suitable bike, with about 150mm of travel, and I will endeavor to hit things as hard as possible. That isn't anything to write home about, though. It has been a real long time since I have broken a rim, and that severely inhibits my ability to deliver solid F.S.U reportage.

BUT, I have rolled several hundred miles on a pair of hoops I built up myself with some prototype FusionFiber rims. I like them. As to reports that they feel "damped" or "quiet" compared to similarly profiled carbon fiber wheels, can confirm. I noticed a definite reduction in chatter compared to the Roval Traverses they replaced; not the squirmy or flexy sensation that some super lightweight wheels can transmit, but less sharp and a little more planted feeling on chundery ground. By way of analogy, swapping over to the FusionFiber wheels felt like I was rolling very slightly bigger tires. I need to spend a LOT more time to determine if this is f'reals feels, or if I am experiencing confirmation bias. For the record, those proto wheels were built up with XTR hubs and DT Revolution spokes, and they weigh pretty close to the same as these.

Time will tell. Let's check back on these things in August.

Comments

BarryW

2 months ago

They might be great wheels, but I'll never be on the side of products that claim to be more environmentally friendly by being 'downcycled'. That's the entire lie of plastic 'recycling'.

You know what works wonderfully and is incredibly sought after for recycling?

Aluminum.

Reply

Mike Ferrentino

2 months ago

Aluminum is as good as it gets with recycling, except for maybe paper. I'm not a fan of plastics in that they represent an extractive end game, or something close to it. There is no way of unmaking them, reducing them back into the soil from whence they came, and eventually the most we can hope for is that we learn how to digest microplastics.

But at the same time, I recognize that ANY manufacturing process, regardless of raw material, uses a massive amount of material and energy. And that ANY toy we ride around on in the woods, regardless what it is made of, came to exist through those massive extractive processes. We are not solving any of these huge environmental issues by riding bikes. But I can still get behind the idea of trying to make the entire process a little less wasteful, a little bit cleaner, even if I know that none of this is going to save the planet.

Reply

Timer

2 months ago

Not buying yet another new toy because it's shiny and has lots of good marketing behind it is, by orders of magnitude, the best thing we can do. Don't need to worry about the manufacturing process when it isn't being manufactured.

And when you need to buy bike parts, buy really expensive high-end bike stuff. Because thats money not spent on other environment-destroying things like flights, cars, electronics or houses.

Reply

the prophet

2 months ago

Nylon is a resin, it is just not the typical resin used for making carbon fiber composites. This is partly due to the lower glass transition temperature of most nylons (ie the rim could get soft if left in the car on a summer day with the windows up) compared to the traditional epoxies used in carbon fiber construction. Nylon also loves to absorb water and then swell, which could be interesting for a rim that is run in humid environments.

The main difference is that the rim is a thermoplastic vs a thermoset which is what most carbon rims currently are. As in you could chop it up, and then remold it.Traditional thermoset rims are one and done.

Revved Carbon (Guerilla Gravity) also had a thermoplastic carbon rim that was ready for production at the time of their demise. Someone bought all of the tooling and material at the recent auction, so maybe another US amde thermoplastic rim is on the horizon. I don't know what resin they used in their patented process, but it was a very high temp cure like their frames.

Reply

Mike Ferrentino

2 months ago

True, I should have been more specific with my language there - nylon is the resin. Thermoplastics are not new, and as you have pointed out, have in the past exhibited characteristics that are not always conducive to making wheels and frames. CSS/Forge+Bond are very tight lipped about what, specifically, they are doing within their process that makes it work the way it does now, but they are also highly confident that it works. I'm leaving the wheels in the car with the windows up today, though. Just to check.

Reply

Cooper Quinn

2 months ago

I'm not sure that's going to be useful - history shows us leaving things in your car isn't a great way to be able to check on them later.

Reply

Lu Kz

2 months ago

Too soon?

Reply

Mike Ferrentino

2 months ago

ouch

Reply

Timer

2 months ago

Is the glass transition point of common nylons really low enough to pose a problem for this kind of application? Most wall anchors are made from nylon, even in very hot climates or wet environments. They can fail when the building is burning, but by that point our bicycle rims are probably of least concern.

Reply

Kos

2 months ago

Intriguing approach, but perhaps a wee bit heavy for each intended use.

Snark Alert: Did a random number generator come up with the name Forge + Bond?!

Reply

Pete Roggeman

2 months ago

The name roughly indicates the manufacturing process.

Reply

Flatted-again

2 months ago

That warranty language bothers me a little. To me, an enduro wheel’s normal intended use is to smash through rocks, over drops, and off jumps, but is that really what is meant by “normal intended use?”

Reply

Mike Ferrentino

2 months ago

I haven't taken a deep dive into the specific warranty language of other wheel brands, but I would be surprised if it was much different. My guess is that F+B would warranty much of what happens "on bike", and that the crash replacement policy is in place for the more egregious things like getting rear ended on the highway with your bikes on the back. Or something like that. I'll follow up with them about it today though...

Reply

Flatted-again

2 months ago

I’d hope so! I think crashes are a part of normal intended use too. It’d be nice if it were the same as we are ones or racefaces- that would definitely sway my decision.

Reply

Lu Kz

2 months ago

Let's compare three brands of warranty language:

Forge + Bond:

- lifetime, but not normal wear and tear, and only "normal intended use". Don't run it over with a car.

We are One

- Lifetime, no questions asked, except no vehicle accidents, incidents, or stupidity.

Bontrager

- Lifetime for defects, two years for everything else*

- *it says only while riding your bikes, but Trek replaced both a wheel ran over by the UPS truck and another melted by an exhaust for free. Your milage may vary.

Of the selected three, there appears to be a good, better, best thing going on, with F+B coming in last place.

Reply

Mike Ferrentino

2 months ago

Bontrager's warranty uses almost exactly the same language as F+B: _"This Warranty Does Not Cover normal wear and tear, improper assembly, corrosion, improper maintenance, installation of components, parts, or accessories not originally intended for or compatible with the bicycle as sold, damage or failure due to accident, misuse, abuse, or neglect, labor charges for part replacement or changeover..." _

Good to hear that they have gone above and beyond, anecdotally, but it is a bit unfair to paint a negative picture of F+B before they have a chance to prove themselves.

Reply

Lu Kz

2 months ago

I think there's a difference between "lifetime, but excluding normal wear and tear" and "lifetime, but excluding normal wear and tear unless it happens within the first two years, in which case we cover anything that happens while riding and won't even charge you labour". I was anecdotally speaking of the two year program, not the longer warranty program.

Reply

Flatted-again

2 months ago

An additional complication could be each companies’ definition of lifetime. Is it the anticipated lifetime of the product or is it the lifetime of the company?

Mike Ferrentino

2 months ago

Reminds me of an old joke about a wristwatch that came with a lifetime guarantee - as soon as any part of the watch failed, there was a spring-loaded razor inside the case that would pop out and slash the wearer's wrist.

Mike Ferrentino

2 months ago

Here's the word from the source, as delivered via email this morning: "You break the wheels while riding your bike—that's everything from pretending to be Mitch Ropelato on whatever enduro line you ride to running it into your wife's Camry while testing out your suspension in the driveway—the team at Forge+Bond is going to cover your wheel. F+B is a small company making badass products with a huge desire to keep their riders happy. Forget to take the bike off the roof rack and run it into your garage? Yeah, they'll probably work with you on that one too. They're not a bunch of suits looking to sweat the T&Cs. Got a problem? Don't speculate and drown in the details. Pick up the phone, send an email. You'll probably make a new friend and even get an invitation to ride the next time you're in Utah."

Flatted-again

2 months ago

Awesome Mike, thanks for getting that clarification. Good to hear they support their customers

Mark

2 months ago

If the wheels survive the heat test a highway crash test would be a helluva a way to write about the durability of these things. Maybe get Cooper to drive just so you're safe.

Reply

fartymarty

2 months ago

Mike - this method of construction sounds similar to https://www.starlingcycles.com/the-starling-cycles-thermoplastic-carbon-fibre-prototype-ebike/#:~:text=Introducing%20the%20first%20carbon%20fibre,or%20more%20specifically%20eMTB%20frame.

Reply

Andy Eunson

2 months ago

What ever happened with those GT thermoplastic carbon frames back in the 90s? Why did they stop making them? Were they problematic in some way related to the material or was it the aluminum lugs letting go? I remember the promotional articles and adds but not much else.

Reply

Mike Ferrentino

2 months ago

If I recall, the problem with them was that they came unbonded from the lugs. Which, given the time and the industry, was pretty commonplace with bonded components, regardless of material...

Reply

Brad Nyenhuis

2 months ago

And, as I recall, weren't they substantially heavier than their aluminum brethren?

Reply

Mike Ferrentino

2 months ago

I can't say. That part of my memory is all scuffed up and there's dirt on the lens. They were definitely not lighter, for sure.

Reply

Brad Nyenhuis

2 months ago

What was KB's famous saying?

Heavy, Expensive, Weak; pick all three? Something like that.

Reply

Please log in to leave a comment.