Crank Brothers Kronolog Review

Dropper posts are the cat’s ass. You won’t find me riding an XC / AM bike without one, if I have any say in the matter. I’ve used a number of different ones over the last few years – both mechanical (cable-activated) and hydraulic – and I’ve had mixed degrees of success with them. Every single one that I have used over an extended period of time, without exception, has had problems at one time or another so I was curious to see whether the new Crank Brothers Kronolog post was as sweet as the company’s marketing hype and YouTube videos promised.

Turns out that it was in some ways, but it also had a few quirks and suffers from a rather significant perception problem. Get yourself comfortable, though, because this isn’t some light-weight review that you’ll be able to breeze through in 30 seconds.

The Crank Brothers Kronolog seatpost, ready for action. It certainly looks pretty…

Specs and Setup

I covered the Kronolog specs in the First Date article, so I’ll just jump into the details – after a quick recap of the way the post works. There are two spring-actuated steel jammers that press against a moveable aluminum quill, one at a slight upward angle and one at a slight downward angle, when there is no tension on the cable that operates the height adjustment mechanism. When you press on the handlebar-mounted lever and put tension on the cable, it pulls the ends of the jammers towards each other and pulls them away from the quill. That in turn allows the quill to move freely. Release the lever and the jammers bite into the quill, at whatever point it is in its 5” travel range. It’s a simple concept that has been used for years on things like pressure rod caulking guns.

The jammers that stop the quill from moving are the silver metal pieces on the left side of the post, about the same height as the “o” and the “g” on the word “kronolog”. The moveable quill is the part sitting above the upper seal.

Before I could use the Kronolog that was sent for testing, I had to change out the stock cable and housing on the post because it was too short for the 21.5” Rocky Element 950 I was testing; the stock cable should be long enough out of the box for most bikes, though.

Changing the cable on the Kronolog is straightforward. Pop off the cap covering the clamping mechanism, loosen the set screw holding the cable in place, remove the cable and housing, grab a shifter cable, cut the correct length of 4mm housing for your bike and then reverse the process to put it all back together. When I re-installed the cable, I used the tension screw at the release lever to take up most of the slack in the lever play but was careful to set it up with the 3-4mm of slack recommended in the instructions. As you’ll see later in the review, this is important to note.

A couple of notes for the cable and housing swap: there’s a VERY small spring in the lever mechanism that keeps tension on the lever. Don’t lose the little bastard when you’re removing the old cable – it’s essential to proper operation. Also, make sure you buy 4mm shift housing; 5mm brake housing doesn’t fit in the bottom ferrule that sits in the lower jammer.

Once you feed the cable through the mechanism, make sure that you sufficiently tighten the set screw that holds the cable in place. I didn’t do this initially because I didn’t want to crush the braided cable, and had it slip on me the first time I pushed on the lever. Fortunately, it didn’t go all the way out past the set screw.

The height adjust mechanism on the Kronolog, with the cover on (left) and off (right).

Cutting the cable itself once it’s clamped isn’t a big deal, but I don’t like the fact that there’s no room for something like a crimp cap to keep the cable from unravelling. Crank Brothers says it’s working on a new type of cable that doesn’t fray. Apparently, you can also use a drop of KrazyGlue to do the same thing. [Or solder, if you’re handy with the steel. -Ed.]

Once the cable was installed, I pumped the post up to 100psi to ensure that it returned quickly. Although the end cap on the post says max 100psi, the printed instructions say 85psi max; after a few rides I ended up dropping it down to 85 so the post wasn’t quite as hard to compress. Apparently, later production runs will say 85psi on the end cap.

There’s some good stuff here…

I started thrashing the Kronolog in March when the weather was wet and sloppy, and quickly realized there were a number of things to like about the Kronolog.

First and foremost is the fact that the cable doesn’t move when the post drops. That’s because it enters the post at the clamping mechanism, which is static at the middle of the post, rather than the head of the post as is the case with most dropper posts. Posts where the cable enters at the head end up with a large cable loop when they are compressed.

The Kronolog ready for action on the Rocky Element 950. It worked very well with the cable routing on the bike, and I wasn’t left with a big cable loop banging against the frame or my leg with the post down.

I hadn’t realized how much of a pain the big cable loop can be until I didn’t have to contend with it. Although I’ve never had a problem with the cable on those posts catching on anything while riding, it tends to rub on your leg and rattle against the frame. Saying goodbye to all of that was a very nice thing.

Second, the post stays in place during the normal course of operations. That may sound odd, but I can’t say that for every dropper post I’ve tried. The Kronolog also felt solid once it was up, which says a fair bit considering that I’m well over 200lbs including gear. Now, I know that a slip-free experience isn’t the case with every Kronolog post out there (just check any number of bulletin boards at various mountain bike sites for evidence of issues people have had with the Kronolog), but it was with mine. According to Crank Brothers, though, there is a reason for the slippage some people experience. More on that below.

Another big plus for the Kronolog is that the lever mount on the handlebar plays well with both Avid and Shimano brakes (and by extension, should also work well with Magura, Formula, Hope and Hayes). It doesn’t require any major compromises to set up, which can’t be said for every dropper post lever – for example, it’s very difficult to make the RockShox Reverb lever integrate with new-generation Shimano brake levers when it’s placed between the brake clamp and the grip. The easy integration on the Kronolog is thanks to a relatively thin bar clamp and long lever. Changing configuration from right- to left-hand set-up is simple as well – something that isn’t possible on the Reverb without buying a new lever.

The Kronolog lever set up with a variety of different SRAM clamps. You can put it wherever you want, based on personal preference. The knurled portion coming into the lever on the left side is used to adjust tension on the cable. In this position, it’s screwed in all the way but would usually be screwed out a few threads for correct cable tension. I made that change shortly after this photo was taken.

The Kronolog design is also well suited to wet climates. The full-length housing, protected end-point for the cable and covered height-adjustment mechanism have kept most contaminants and water out of the mechanism and cable housing – in spite of Vancouver’s often shitty wet weather and the post-ride bike wash that’s necessary in those conditions.

Performance of the Kronolog HA system and the cable itself remained very smooth after several months of “normal” use, which hasn’t been the case with other mechanical dropper posts I’ve used around here. In fact, I’ve had such bad luck with other mechanical posts suffering from contamination and failing as a result that I’d almost written them off for the Shore. The Kronolog was able to handle the conditions admirably, which is a big mark in its favour.

As well as some so-so things…

There are a few things about the Kronolog that I don’t particularly like. Some of them are personal preferences, though, and some are characteristic of the Kronolog so they aren’t necessarily knocks against the post design itself.

My biggest issues with performance are related to what happens when you push the lever to allow the post to return to full height. First, the post slows down as it nears the end of its stroke. Second, there’s no top-out noise that lets you know it’s at full height. Because of both of these things, I found myself pushing the lever harder and holding it longer than is likely necessary.

Crank Brothers says you can deal with both of these by disassembling the post and taking out the top out bumper o-ring and another o-ring that slows the return at the end of the stroke. I did that, and there’s now a small top-out noise but it’s not as distinct as on other posts like the Specialized Command Post (which is loud enough to shock you the first few times it slams to the top) or the RockShox Reverb (which is audible without being frightening).

I also found that the return was still slower than I wanted. Normally, that would be something I could live with, but I used the post during an endurance race and found it annoying to listen for the top-out or wait for full extension rather than focusing on the race itself.

There are a number of o-rings on the Kronolog damping unit. I removed the o-ring on the right side of the main shaft (top out noise) as well as the one just to the right of the threads with the Loc-tite on them (rebound speed), and while it did change things slightly I still didn’t love the result.

Another annoyance that is more than functional issue is the fact that the post sinks ~ 2mm when it’s weighted, both at the top and the bottom of its travel, and makes a rather noisy clunk when it does. That’s normal, according to Crank Brothers. Whether that’s “normal” is somewhat irrelevant – it’s annoying, and doesn’t sound like a happy noise. More on this in a minute…

I’m also not wild about lever feel on the Kronolog. The lever itself isn’t exactly the most ergonomic thing in the world, although it does look pretty with the Crank Brothers logo forged into it. I didn’t find the lever action particularly light, even compared to some other mechanical posts I’ve used. It feels a little like a shifter cable that’s a little gunked up. Nothing major and certainly not a deal breaker, but I’ve been (admittedly) spoiled by the smooth action on hydraulic posts.

Be prepared for performance of the moveable portion of the post to deteriorate somewhat over time, especially if you’re riding in wet conditions. Crank Brothers says that you can add some Tri-Flow to the seal and fork lube like Slick Honey to the quill to improve performance. I did that and cycled the post a few times, and it helped things somewhat. It didn’t restore the post to that new feeling, though.

Some dropper posts have noticeable lateral play when you grab the saddle and move it from side to side, but there’s none of that on the Kronolog. Crank Brothers talks this up, but I think it’s actually a bit of a non-starter. It’s hard to notice the play on other posts unless it’s particularly bad and/or you’re moving the saddle by hand. So, yeah, the Kronolog doesn’t move but I’m not going to lose sleep over play in the post (or lack thereof) if the post goes up and down the way it should.

And then there were the issues…

Google “Kronolog post problem” and you’ll find quite a few forum posts from people who are having issues with their Kronolog. They go on for pages and pages and pages. The biggest gripe from most people has been the post’s inability to stay up. Other people have questioned the notch that forms in the back of the quill and what appeared to be premature wear on the post.

Fortunately, I didn’t have any issues with my post staying up but after several months of testing, the notch in the back of the quill was noticeably deep. It looked like it was almost 1mm deep, and that didn’t seem right to me. I certainly wasn’t expecting that to happen, and was concerned that it would just keep getting deeper over time and ultimately compromise the post’s safety.

Based on the reported issues with reliability and my own concerns about the notch in the back of the post, I didn’t have a lot of positive things to say about the Kronolog when I wrote the first draft of this review. At best, it seemed like there were serious quality control issues with the Kronolog, and at worst that it was poorly designed and inadequately tested. And I wasn’t the only one who felt that way: there have also been a number of negative Kronolog reviews from other mountain bike test editors on other sites.

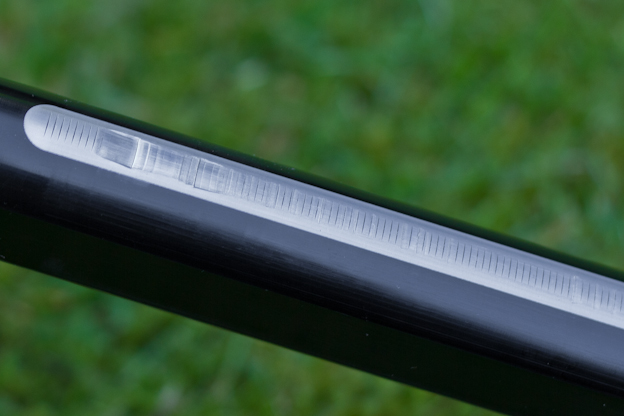

A close-up of the notches that formed on the backside of the quill. The largest one is at the top (left side) of the quill, where the upper jammer locks onto it when the post is fully lowered. It’s ~1mm deep. The slightly smaller one immediately to the right of that is where the lower jammer grabs the post when it’s lowered. There are multiple other notches of varying depths along the length of the quill where I’ve stopped the post. I wasn’t expecting to see this, and it raised concerns about safety as well as long-term durability.

Before posting the review, though, Cam McRae and I decided to give Crank Brothers a chance to comment on the whole situation. And what we heard was pretty interesting.

My first question to Chad Peterson, project manager at Crank Brothers, and Amanda Schaper, their marketing manager, was pretty direct: why have so many of the posts been failing? And their response was unequivocal: they haven’t been. According to Crank Brothers, the posts have been suffering from setup issues that are masquerading as failures.

“We are hearing market feedback that some riders are experiencing slipping issues with the Kronolog seatpost,” said Schaper. “This is primarily due to a setup issue. During our thousands of hours of testing, we always set up the remotes and cable housing perfectly. What we have learned recently is that the set-up is not black and white, and not always intuitive. There is a grey area in between a perfect set-up and a failed set-up. This grey area makes the post function well initially, but could cause premature wear.”

Peterson also noted, “Additionally, some of the early Kronolog seatposts that we shipped from the factory had a tighter cable adjustment. If a rider took the post out of the box without adjusting cable tension, the cable was likely too tight, causing the post to slip due to the jammers [the clamping mechanism] being actuated. We take full responsibility for riders setting up the seatpost properly.”

The knurled cable tension adjuster is the cause of much heartache and headache, according to Crank Brothers. In this photo, it’s screwed all the way in. It can / should come out a little, but there’s a really small window to work with. Too far out and it puts tension on the housing, which pulls ever so slightly on the jammers, meaning they’re not holding the quill in place. In this condition, when riders sit on the saddle, the post creeps down, seemingly for no reason – when in fact the reason is a setup issue, not a functional issue with the post.

Do I buy that explanation? It’s certainly plausible. Too much tension on the cable pulls on the jammers ever so slightly, and rider weight causes the post to slide down. Without knowing how finicky the set-up can be, riders naturally assume that it’s the post failing.

The fact that I DIDN’T run the post with the factory settings – due to the cable change before the first ride and by-the-book adjustment of tension when I installed the new cable – and then didn’t have any issues with slippage would certainly support Crank Brothers’ explanation. I also asked about cartridge / mechanism failures, and CB says that the incidents of these has been negligible (in the single digits). Assuming that figure is correct, it would also support the cable tension and set-up explanation.

Ok, so that explains the posts slipping. But what about the notches that form on the back of the quill? They just don’t look right. I wasn’t expecting that to happen, and neither was anyone else in the MTB press corps from the sounds of things; it made me wonder whether the post was safe.

According to Peterson, “The notching is completely normal, and it’s how the post is designed to function.” The steel jammer bites into the aluminum quill when cable tension is released, stopping the post from moving any further. It takes ~2mm to bite – the 2mm of settling that I mentioned – and the clunk happens when it bites into the quill. Over time, that process creates a notch, especially when the jammer repeatedly stops at the same point on the quill.

Travel on the post is infinite within the 5” range, so there can theoretically be notches at any point. Most will be relatively small, but larger notches will form where the quill stops repeatedly. Peterson conceded that will be most common at the top and bottom of the travel range, leading to notches that are larger, and deeper, than the others. Which is precisely what I noticed at the top of the quill on my test post.

With regard to safety, Peterson noted that “The jammer is 0.6mm deep, and it should be impossible for the notch to go any deeper than that. Once the notch reaches a certain depth (less than 1mm), it will stay there forever and not get any deeper.”

As for the notch’s effect on the post’s overall safety (i.e. is it creating a weak point?), it “does not affect quality, performance, or safety. To be sure of this, we tested Kronolog seatposts that were notched to the maximum depth, and they passed CEN fatique testing with no problem. We have had no failures of the post due to cracking or catastrophic failure.”

A close-up showing the size of the notches on the quill. The markings are centimeters.

Schaper also commented on the safety issue, saying: “Prior to its release, we put the Kronolog through extensive machine and ride testing so that we could have total confidence in the product. During development, the Kronolog was tested for fatigue, cycle, load, rotational play, and clamp slip and push. The European fatigue testing standard is 100,000 cycles, and the Kronolog went to 270,000 cycles, passing at 2.7 times the European standard. Our product development team has put the Kronolog through extreme ride testing, and numerous professional athletes have been involved in the ride testing process, including Hans Rey, Richie Schley, Chris Van Dine, Jill Kintner and Bryn Atkinson.” Ok, sure. Not having been there, I can’t say that’s a fact but I’m willing to believe it.

So, what about people who have already bought a Kronolog and are having issues with it? “Crank Brothers is and always has been a company that stands 100% behind our products,” said Schaper. “If anybody experiences any type of problem with their Kronolog, we will work with them to make it right. We encourage customers to contact us for assistance in setting up the Kronolog. We will happily walk them through the process and answer any questions that come up along the way. To make this easy, we’ve set up a Kronolog hotline that will connect you directly with our lead Kronolog tech expert. They can call 1.855.929.6322. If the toll free number doesn’t work [which it might not from outside the US], people can call our customer service line at 1.949.464.9916 and ask for Nick.”

One final issue I had with the post was with the small bridge piece that sits between the saddle rails. It cracked when I was assembling the post the first time. Yes, cracked. It’s plastic, and apparently it has to be positioned very precisely between the saddle rails when you are tightening the clamping bolt. Crank Brothers says it went with plastic for weight savings, but that seems somewhat akin to spec’ing your DH bike with carbon headset spacers to drop some grams. A word of caution: be very careful during the install to avoid this headache. Small parts like a new bridge are sure to be hard to come by in a hurry. Crank Brothers is monitoring the situation for other reports of failures.

Final Thoughts

So, where does that leave us? The Kronolog I tested works as advertised and I really do like certain things about it. The fixed cable length, the fact that the system is sealed from the elements and compatibility with different brake systems are all good. I can live with the slow return and lack of a strong top-out noise, but they can be a minor distraction when you’ve got better things to focus on – like the trail during a race. The lever feel isn’t great, I’m not a fan of the clunk that accompanies the jammer biting into the quill and the plastic bridge could be a royal pain in your ass if it cracks.

But when the post is working properly, it does what it’s supposed to do: get out of your way to allow faster descents and then return to full height so you can sit and pedal. Mine also stayed where I wanted it, and it withstood months of abuse in seriously inclement weather under a very large rider. Other Kronolog posts SHOULD do the same, as long as they are set up properly (and assuming that that is really the issue).

Tristan Rayner was thankful that the Kronolog was doing its thing so he could ride this steep ramp on the Shore.

Regardless of how the post performed and the positive attributes that it does have, however, the setup / apparent failure issue is a huge public relations snafu for Crank Brothers. Add to that the notch issue that people weren’t expecting, and you’ve got a buying public that doesn’t have a lot of confidence in the product. And it’s hard to blame people for that.

The whole situation is unfortunate. Crank Brothers had good intentions when it started from scratch with the Kronolog rather than slapping another Band-Aid on the Joplin post design that it acquired from Maverick, but the Kronolog fell flat on its face due to some serious communication and perception issues. Whether Crank Brothers can recover from the Kronolog PR problem remains to be seen.

As for whether you should buy a Kronolog or not, it’s really tough for me to come down on one side or the other. And that’s unusual, because I’m normally quite opinionated – especially when it comes to bike stuff. Ultimately, it’s your call. I’ve laid out the pros and cons. It might be a bit of a risk, but if it really is a matter of set-up then this is a pretty darn good mechanical post. One of the best I’ve tried to date, actually.

Kudos to Crank Brothers for addressing the issue, but I simply don’t have enough information to go on to say that it’s all good with any certainty, so I’m stuck in the “undecided” camp. Maybe a few months of positive online feedback and a drop in reported issues would change my mind. Until then, I’m going to hold off on the unconditional endorsement.

It is interesting to see that Stuart’s criticisms of the Kronolog don’t align with the majority of complaints floating around the intertubes. The aluminum quill appears to be a wear item, and from our perspective, putting a 6’4″ heavy hitter on the Kronolog was the ultimate test for this dropper post. While Stuart hasn’t exactly seen a failure, he has valid concerns. Have you had any experience with the Kronolog? Chime in below…

Comments

Please log in to leave a comment.