SRAM XX1 On Trail

SRAM announced the XX1 11-speed drivetrain earlier this year, releasing some shady photos and, later, a video showing the new derailleur in action. Crankworx Whistler was the first these pieces had made their way into our hot little hands. Seb’s had the chance to ride the system not only for the one day media launch, but for the past ten days; here are his thoughts.

SRAM XX1

It’s not one more, it’s less is more.

Words by Seb Kemp.

With a dusty chalkboard on the wall, well heeled desks laid out in a grid, and lockers lined along the walls I really feel like I’m back at school. Fortunately, this is SRAM’s School Of The Mountain and the professor is Chris Hilton (SRAM’s external drivetrain product manager). Assisting him is headboy Greg Herbold, he of the rainbow stripes and even brighter personality.

I’m trying to keep my composure while chasing down Curtis Keene on the Top Of The World trail in Whistler. Note how composed the drivetrain is. Photo ~ Adrian Marcoux

The reason why class is in session (and why I’ve perched myself at the back of the class) is that SRAM want to run the new XX1 drivetrain by us. For those who have been spending too much time huffing glue or hiding behind the bike shed, XX1 is the new 11-speed drivetrain that has integrated a bunch of recent technological advancements and also features a few very different, and perhaps revolutionary, developments.

In due time we will get to the features, but first Chris Hilton wanted to explain why SRAM developed XX1. “Last year we were focused on developing the Type 2 rear derailleur and overhauling Gripshift. We completed them and found that we had a little time and freedom to play with concepts and ideas that we, as bike users, wanted on our own bikes. Ten speed has been very common on many riders bikes, so we asked if we could make a 1X drivetrain that was better. 1X10 means often packing a hard gear and grinding or spinning out so what we did is not exactly add gears, but take the benefit of a large spread of gears that you have on 2X or 3X drivetrains and distill it down.”

That is it, just five parts make up the complete XX1 drivetrain.

And that’s about that. It is not about more gears, but having less gears.

So, now we have covered the why (we will, however, be returning to why later) let’s look at the how with a mathematics, science and philosophy class all rolled into one.

SOLO

Up front everything looks different. The chainset looks tidy, uncluttered, neat, so much so that it looks unfinished. That is because rather than having an awkward looking front derailleur, numerous rings and perhaps a chain device, the XX1 drivetrain has just a lonely chain ring with no additional appendages.

Just one up front and all on show.

The chain ring has deeper teeth that are hooked on the inboard side and alternate teeth have a cross head pattern to them. SRAM found that because the chain doesn’t need to derail from any chain rings they could figure out a way to simply design the chainring to hold the chain instead. The chain and the chain rings synchronize, creating a neat interface, rather than a loose fit that is designed to shed and release from each other.

Take a look at a traditional drivetrain, the top section of the chain when under load is pulling from the chain ring to the cassette. It is under a huge amount of tension, whereas the bottom half is under low tension. The bottom half is where it becomes easy for the rear derailleur to shift smoothly across a cassette (any cassette regardless of teeth count) because there is not a tremendous pressure on the chain. However, for years we have been satisfied trying to derail the chain when it is under this huge tension just so we can get extra gears.

We can see here the crosshead profile of the teeth but also not quite visible is the hooked profile of the inboard side of alternating teeth.

The beauty of the 1X11 set-up is that now there is zero need to disrupt the upper most section of the chain drive from doing what it is supposed to do – which is deliver power. All the shifting is dealt with at the rear of the drivetrain which is a smoother and simpler place to do so, leaving the least tensioned section of chain to slip easily between gears when required.

It’s pretty straightforward isn’t it? It’s almost baffling that we have gone on so long placing an unnecessary weakness and stress in the drivetrain.

Even so, the solo chainring looks almost too exposed, naked even. It really doesn’t look like it will stand up to abuse or even hold a chain.

The chainring claws at the chain on the bike and off the bike. After ten days of solid vertical chasing the chain has not let loose once. Remarkable and not just marketing spiel. Photo ~ Adrian Marcoux

However, it does. The teeth and the chain are designed to mesh and match. While fiddling with a chainring and chain (at the back of the class when I should have been paying attention) there is a perceptible gripping of the chain to the chainring. As I played with it I must have had a baffled look on my face because Herbold jumped up and added his two cents, “It’s like the chainring has magnets on it holding the chain.”

It does appear to be quite different. When class was adjourned we headed out to the Top Of The World to try it out for ourselves. After nearly 5,000 feet of descending the chain had not even given a hint of derailing or dropping. This was over fast, rough, terrain in the alpine that dropped us into the Garbanzo Zone where we hurtled into blown out, holey, rooty, sqaure edged messes like No Joke. It really did stay on, and in the week since I have been riding the drivetrain it has still yet to drop.

It is so simple that it is hard to believe it is that clever. But it is.

UNA MASS

The cassette is not a Spinal Tap punchline. What starts out life as a raw 5lb lump of billet sits on five axis CNC machines for eight hours until it becomes the complete X-Dome 11-speed cassette cluster (minus the largest cog which is pressed on afterwards).

It is expensive and different, but this is the start of something beautiful.

The cassette is humongous. The 42-tooth cog is the same size as the 180mm rotor on the bike. The steps between the gears are even across the cassette with no wild jumps. While shifting it felt smooth and easy, no different to any other quality drivetrain.

To fit the wider cassette, SRAM had to redesign the cassette body. Unwilling to force another hub width standard, or mess with the dish of wheels, what they did was radically alter the driver instead. Drivers are only available on DT Swiss and SRAM wheels at the moment, but SRAM have got an open plan policy on this and I’m sure it won’t be long till other hub manufacturers join it.

That’s a 180mm rotor matched up to a 42tooth cog. Pair the 42 tooth up with a 34tooth, or even 32 tooth chainring and you can climb ANYTHING that your own legs will allow.

Some of the changes to the driver include moving the cassette lock ring from outboard to inboard. SRAM believe that the the traditional placement of the lock ring is focused on the point at which least torque is being applied, but with their system the cassette and driver interface is locked towards the larger rings, where most torque is being applied. This also creates a solid interface with no tumbling (have you noticed the notches on your driver body before? That is where the cassette is ‘tumbling’ on the driver because it is not locked correctly).

These more discreet engineering solutions are not immediately recognized on the trail after just one week on the product. Only time will tell whether the developments in XX1 cassette and drivers are a genuine improvement.

So simple that even a monkey could figure it out. So good that you’d have to be bananas to not ‘get’ it.

OLD AND NEW.

SRAM is often referred to as a marketing company with an engineering problem. Chris Hilton’s anecdotes and the evidence of recent technological developments in drivetrain, brakes and components from SRAM would seem to suggest it would be an unfair statement to make of the boffins in Germany, Colorado Springs and elsewhere who do the hard graft of designing.

“The idea of large spread cassettes came about from an entirely different direction. Engineers had being playing with this idea for a while and that’s how the horizontal parallelogram came about.”

The words in the photo say it all.

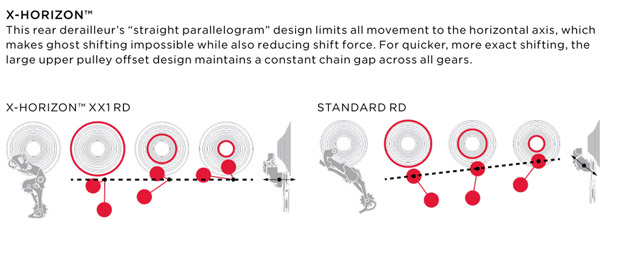

To clear the massive cassette (currently opening up to a side plate sized 42 but with room for expansion say SRAM) the rear derailleur needed a few changes. Current rear derailleurs typically move in a diagonal motion – inward and downward. The XX1 rear derailleur with its “horizontal parallelogram” design and pulley offset (called X-HORIZON™) keeps the chain gap constant across all 11 gears.

SRAM says, “Paired with the XX1 shifter, the X-HORIZON RD forms the backbone of X-ACTUATION™ technology for unbelievably smooth shifting action.”

As well as all this X-rated action at the rear, the derailleur features Roller Bearing Clutch technology which on this week’s rides has meant a silent ride and, no doubt, contributed to keeping that magnet chain on the magnetic chain ring.

It also borrows another older technology, the Rollamajig. This means less friction on the cable for shifting duties and a lessened chance of severed cables.

Note the old technology. Remember Rollamjigs the first time around? Photo ~ Adrian Marcoux

WHIPS AND CHAINS.

One thing that has unnerved people is having an even narrower and therefore weaker chain. Well, fear not. Because the chain doesn’t need to do double shifting duties anymore, and doesn’t need to be able to climb and fall from chainrings SRAM can design a simpler chain that might not wear out so fast. As I said earlier, now that the chain doesn’t have to be forcefully derailed while under the tension of propelling the rider, it shouldn’t be subject to even half as much abuse. Supposedly, SRAM have applied a proprietary finish that makes the chain better, faster, stronger and perhaps better at remembering your brother’s birthday, but I can’t comment on that yet. Again, more time on the drivetrain will be the real test.

Top Of The World to Whistler Village by way of No Joke and there was no chain noise, ghost shifts, mis-shifts, dropped chains or curse words aimed at the drivetrain. This product is not just a company trying to sell you more and more stuff you don’t need, this is a clever solutions applied to real world problems.

IS IT THE END? MY ONLY FRIEND, THE END.

This isn’t the end for multiple chainring drivetrains as we know it. But it could be for you. I personally believe this is a great and logical step for drivetrains. Sure, we might still have the dangling protrusion of a rear derailleur, but 11-speed does away with the pesky mess of front derailleurs.

This is our test rig for the XX1, a 2013 Specialized Enduro S-Works. This bike likes to climb and really likes to help throw caution to the wind on the downs. An ideal bike to test out the XX1 capabilities.

SRAM accept that not everyone will suit 1X11 so they will continue to develop 2X10 drivetrains and components, but for those people that have seen the light of running 1X10 or have been sat on the fence wanting to but were reluctant to lose the easy turning of a granny ring, then 1X11 is a legitimate option.

In one week of hard riding the chain has not once dropped. There may be riding conditions and terrain that does cause it to drop, in which case having a top guide could be a good addition, but for most riders, it probably won’t be necessary. I do wonder about the exposed underbelly of the front chainring though. In the Sea to Sky Corridor there are many log overs and rock hops that might necessitate a little bashguard but this is referring to a small addition for a small subset of riders.

Since this photo was taken the rear derailleur has taken two big knocks. All that has happened is that the damage is purely cosmetic. I’m not saying the XX1 derailleur is tougher than most, but it sure isn’t a sissy.

One person commented that 11-speed is only good for those who don’t have much climbing or descending in their regular rides. I almost lost a rib guffawing so hard. After punishing myself with rock wall climbs up to Gargamel, Kashmir and the Flank trail in Whistler I can safely say that 11-speed is all you will need. Rather than having all that mess up front just for the benefit of a granny ring escape gear, you can shed it all and have the bare necessities on the rear. This means that one gear is all you need. How many gears do you need on your granny ring anyway? If you are using your granny ring for anything but spinning up walls in the biggest cog then you are doing it all wrong.

Getting rid of the front derailleur also means saying goodbye to slow, difficult front shifting, just a seamless one-more click of the right thumb when you really need it.

More so, SRAM say that although the XX1 components are not lighter than the XX brethren, the overall drivetrain is 200g lighter. It isn’t about adding another gear, it is about getting rid of a lot of pieces. Simplicity is about less not more.

So simple that it seems crazy that we have relied on so many extra bits and bobs for so long.

I’ve been a hater of front derailleurs for quite sometime, but I admit that occasionally I’ve almost broken down and wished for a granny ring. XX1 is not just a cheeky marketing gimmick that is designed to make last years brand new technological revelations obsolete, it is truly a step in the right direction for better bikes and better riding. After riding it for the last week (the only media chappy who has been privy to a longer test) I am absolutely bowled over by 11-speed. I don’t want to hand back the bike and will willingly do more homework out on the trail to really put the drivetrain through the ringer.

Yes, it might be one more thing to buy and it might seem extraordinarily expensive but the trickle down effect is no doubt in process. Forget all the other big numbers that are spinning into catalogues right now, 11-speed is the one that really makes a difference.

Curtis Keene, the Brazillionaire, has been focusing on Enduro this year and has some incredible results. He is fast, very fit, skilled and well prepared. He also has Specialized and SRAM in his corner. A winning combo.

UPPERS

– Simplicity

– Cleaner bar and cockpit. Greg Herbold calls it the “rodeo feeling” whereby you can grip for dear life with you left hand and have all your controls on your right thumb.

– Better bikes – engineers won’t have to fit a front derailleur into the crowded BB junction anymore, something which has made short chainstays a problem for some bikes.

– No more front derailleurs, all forty different types of them.

– That escape, climbing gear is only just one thumb away now.

– Lighter.

– Easier to clean.

DOWNERS

– Cost. Yes it is extraordinarily expensive but there are cheaper options coming I’m sure.

– Will it wear out and lose the magic magentism? Only time will tell. Perhaps an 11-speed chain and ring gauge is necessary to tell you when the magic is dying. Or perhaps we might see better longevity with this simpler system.

– It’s not one speed.

– What about bumps and bruises to the exposed chainring? Will a bashguard of some sort be necessary for some riders?

Would you like to turn your cranks through some XX1? Or does it just turn you cranky? Sound off below…

Comments

Please log in to leave a comment.