2014 Crank Brothers Cobalt, Iodine, and Opium Wheels

Mountain bikers are weird people. We obsess about the latest and greatest parts, but often shy away from putting them on our own bike. And if it’s a bit too out there, we want nothing to do with it. Maybe we’re just practical? Maybe we’re sick of being used as cash-spewing, beta testing guinea pigs?

Crank Brothers wheels seem to me to be the poster child for this syndrome. Remember when these things came out? They just seemed all kinds of wacky, crazy, advanced, interesting and totally frightening. Everybody was curious but that curiosity seemed to be about as far as it went. I’ve never seen a pair out on the trail. Not once. Well…other than in Laguna Beach where they’re on every single bike.

But I started thinking about this a few weeks ago. Current mountain bike wheel technology is kind of stupid. Look at all the things that have drastically changed on mountain bikes in the last 10 years, yet, wheel design is roughly the same as it was, what, 50 years ago? Yes, advancements have been made in materials, axle specifications, disc specific designs, and so on. But other than dirt bikes, what other high performance vehicle is still rolling around on conventionally spoked wheels? The basic design is crazy. A skinny little aluminum beam held in place by 32 (or fewer) tiny pieces of wire that pull the beam in alternating directions? And the beam has holes drilled through it and then 32 little pieces of brass/aluminum pull with high force right where the hole is drilled? And the skinny little pieces of wire have a bend in them right at one of the highest stressed points? And now… man… now, we’re trying to seal up that drilled aluminum beam with thin strips of rubber, tape and goop just so we can run our tires without tubes? It’s crazy.

And this crazy design means that wheels are voodoo witchcraft for mountain bikers. The advent of high dollar, pre-made wheels has alleviated this somewhat, but search any bulletin board and watch the frantic “does anybody know a good wheel builder?” discussions. A well-built wheel can be magical. A poorly built wheel is a frustrating month followed by a search for a better wheel builder. And tubeless? Good lord. Everybody has their special sauce technique for doing tubeless the “right” way.

I look at the Crank Brothers wheel design and what they’re doing makes a lot of sense. Granted, I might be a little biased right now, seeing as they just flew me down to California, pimped out my bike, destroyed my out of shape ass on some local trails and then filled me up with beer, information and appetizers.

The Ghost is starting to look a bit fancier. Sorry for the subpar sharpness. Took this photo after a couple of post ride beers.

Why don’t more people buy these wheels?

Diving right in to the mystery, Crank Brothers had some theories on this. “Our first hubs were crap. We had second rate manufacturing and an impossible time with quality control.” Yes. That will do it.

With that feedback, they set about improving their hub design and overall quality. The last generation of wheels (MY 2010-2013) featured a complete hub redesign and new vendors all around. The current hub warranty rate is “below 1%”, and they’re confident enough in their hub that it remains untouched on the new generation of wheels.

Still, how do you trust a company that put a shoddy product out in the first place? How do they recover? After all, there is almost nothing as frustrating as watching the new generation of a product getting rolled out while the company crows about how much better the new version is compared to the now-inferior piece they sold you last year that is currently mounted to your bike. But Crank Brothers seems to still be processing warranty claims on that first generation of wheels and say all the right things about their motivation to keep customers happy. Feel free to chime in if you have experienced something other than this with your Crank Brothers product, but I got the impression that they were the kind of people that will take your phone calls if you aren’t happy.

Crank Brothers isn’t alone on the hub issue: there are a lot of companies that have jumped in to wheels with a sub-par hub offering. I think that there is more than just a poor hub reputation that holds more people back from purchasing these wheels. I think that there’s just an inherent oddness to them that people can’t wrap their heads around. They’re too different. People love Dim Sum, but order up a plate of chicken feet and watch them run screaming from the restaurant. These wheels are chicken feet: the converts will insist that they’re the best things on the menu but the toe dippers are too scared to dive in.

Spoke tabs, hollow spoke pins, post finish machining and laser etched logos. A lot of tech crammed in to not a lot of room.

What did they do right in the first place?

So the company admits that their hubs sucked and they’ve paid the price for that. But everything else about the wheel design has been a winner for them. Structurally, this is a design that makes sense. The company suggests that wheel structure related warranty claims are fairly minimal (i.e. spokes, rims, nipples) and mostly a result of crashes, vehicle mishaps and large trailside sticks. When I asked them about the cost of replacement spokes and nipples, at first nobody seemed to know what the kit cost ($25 gets you 4 spokes and nipples) as they claimed that they don’t sell many of them. I think they’re really on to something here and there are a number of specific advantages:

- Paired spokes. You want your wheel to run as straight as possible, yet the basic wheel has spokes pulling the rim in opposite directions. Alternating spokes aren’t really structurally stable. Pairing the spokes and having them pull from the same point enhances rim stability. The trade–off is that the gaps between spokes will be larger but I don’t think this is an issue.

- No holes in the main body of the rim. This makes for a stronger rim and a far better seal for tubeless tires.

- Dedicated spoke mounts. Crank Brothers mounts their spokes via a dedicated flange rather than via holes in the main body of the rim. The spoke/rim interface is larger and the whole thing allows for a degree of optimization and isolation for how the different loads in the wheel are carried.

- Shorter spokes. When you consider that almost half of your “spoke” length is actually a big-assed aluminum nipple, the actual spoke is very, very short. When asked about nipple failure, they couldn’t remember the last time a nipple was the principal point of failure.

- One spoke length. Each wheel model size has one spoke length. Front, rear, drive, whatever – all the same spoke size.

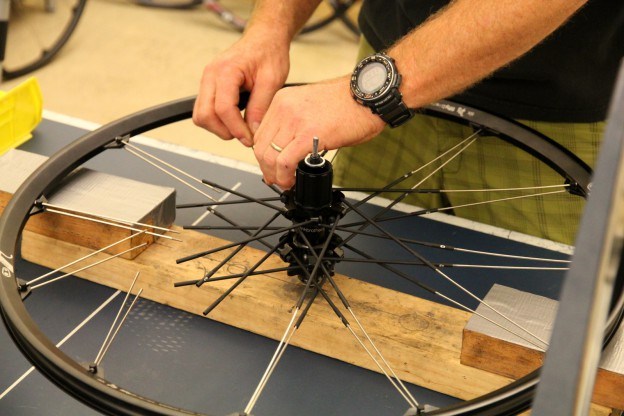

- Easy spoke repairs and wheel builds. You can swap a spoke or nipple out without removing the tire, disc or cassette. We watched a wheel get built (almost to completion) in about 15 minutes.

What have they made better?

I mentioned that hub improvements were the major point of focus for the previous generational re–design. This time around the focus was everywhere else. As a result of rigorous FEA analysis, machine and real world testing, Crank Brothers has made the following changes:

Wider Rims

All three wheel families have had their rim profiles widened by 2mm.

Deeper Rim Sections/Taller Spoke Tabs/Shorter Spokes/Greater Spoke Angle

Here is an interesting article on wheel stiffness and dimensions. With deeper rim sections, and taller spoke tabs, Crank Brothers was able to increase the spoke angle and shorten their spokes. This leads to a stiffer and stronger wheel.

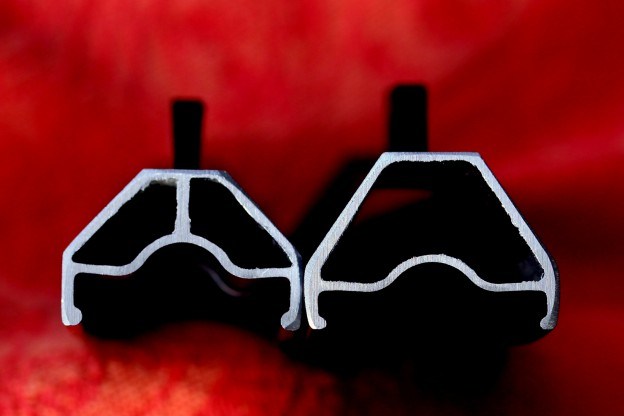

Shorter Rim/Bead Walls

I’d never thought about this one before. With shorter rim walls, a rock or curb or whatever needs to put more force into the rim to cause the wall to bend. So, less rock dings.

Tubeless Optimized Rim Design

As more and more people make the switch to tubeless, Crank Brothers is designing their rims for tubeless. A large part of their focus was in getting the bead to seat with more authority. By angling the rim down towards the bead wall, the bead will be more likely to remain seated. Crank Brothers claims a floor pump is generally all you need to get your tubeless setup seated.

Better Finishes

All rims are now bead blasted, resulting in a tougher surface. All graphics are laser etched and 3 series wheels are getting additional post finish machining, as well as multi colour anodizations. Colours have been toned down from past retina-scalding colourways.

XD Driver

An XD 11-speed driver is available for all wheels. The swap is an easily made with a couple of common tools.

What are we left with?

All of the above changes are made to all three families of Crank Brothers wheels (Cobalt – XC, Iodine – AM, Opium – DH).

Cobalt Family

- Available in 26” (Cobalt 2), 27.5” (Cobalt 2 and 3) and 29” (Cobalt 2 and 3)

- 15mm front, 12×142 rear, and includes end caps for 9mm front, 10×135 rear

- Cobalt 3 weighs 1650g in 27.5”

- Cobalt 3 receives lighter spokes, hollow spoke pins, aluminum freehub body and additional post finish machining over Cobalt 2

- Cobalt 2 – $600

- Cobalt 3 – $900

- 2 Year Warranty

Iodine Family

- Available in 26” (Iodine 2), 27.5” (Iodine 2 and 3) and 29” (Iodine 2 and 3)

- 15mm front, 12×142 rear, and includes end caps for 20mm front, 10×135 rear

- Iodine 3 weighs 1780g in 27.5”

- Iodine 3 receives lighter spokes, hollow spoke pins, aluminum freehub body and additional post finish machining over Cobalt 2

- Iodine 2 – $600

- Iodine 3 – $900

- 2 Year Warranty

Opium Family

- Available in 26”, 3 level only

- 20mm front, 12×150 rear, and includes end caps for 12×157 rear

- 2100g

- Hollow spoke pins, aluminum freehub body

- $900

- 2 Year Warranty

I managed to get out in front of Hans for about 5 minutes and snapped this shot on some typically nasty, dry, rocky, sidehilly Laguna trail.

While I sucked wind at the top, Bill Freeman took this photo of Laguna Beach Local Richie Schley on the down. You should hear what this guy says about winter now. “Why do I need snow when I can wear shorts every day.” Sacrilege.

What they could do to make these wheels even more appealing?

I mentioned this several times to several Crank Brothers employees: Include a couple of spare spokes and nipples with each wheel.Especially considering the effort made around including various end caps, why not throw a couple of spokes in to the package so the consumer isn’t worried about waiting around if they break a spoke?

As well, I am actively encouraging every company that I come in contact with to offer up a Santa Cruz-style direct parts catalogue. There is something very, very reassuring about knowing that any part you need is just a simple and reasonably priced click away. It may be a bit trickier to handle with components, due to all the different distributors and what not, but something like this will definitely take another excuse away from consumers.(Crank Brothers points out that they don’t have a catalogue, but they will sell you parts if you send an e-mail to [email protected] which is probably a far easier solution than what I propose.)

Beyond that, what I love about this wheel design is the potential. Traditional wheels face many, many constraints but the Crank Brothers system seems a great platform for future innovation. Offset, zero dish flanges? Longer flanges? Composite spoke blades.

In Conclusion

I am excited about these wheels and I’m looking forward to how they will perform in the long term. The fact that these wheels don’t use off-the-shelf parts might scare people away, but seeing as “standards” are rapidly dissolving on mountain bikes and parts are generally an overnight shipment away, this could become less of an issue. People like thinking that they can walk in to a shop and get a new wheel built without too much hassle. I think Crank Brothers’ biggest challenge is going to be convincing people that it won’t be a big deal to get a hold of replacement parts and that this “risk” is worth it in the end.

If the wheel is going to last longer than something with a more conventional build then this is a price worth paying, if you ask me. With that in mind, the final question I asked Crank Brothers was this: how long have Richie Schley and Hans Rey been able to get out of their wheels? The answer – both ran prototype Iodine wheels for 6–8 months with zero issues before switching to pre-production models. If those guys aren’t hearing a peep after 8 months, you’re probably going to be alright, judging by what I saw of the trails in Laguna and hearing about the mileage those two put in.

Are you ready for the traditional offset rim and spoke paradigm to be superseded?

Comments

cam

10 years, 3 months ago

Not quite a 'review' but entertaining as always. Was Charlie actually at the launch? Was Richie mean to him? lol

Reply

PinkRobe

10 years, 3 months ago

Review of the 2014 Crank Brothers Wheels:

Reply

mtbjunkie

10 years, 4 months ago

Dings in the rim.

Reply

mtbjunkie

10 years, 5 months ago

I own what I believe is a 2013 set of Iodine 2 wheels, for what it's worth.

Reply

mtbjunkie

10 years, 5 months ago

I own a set of Iodine 2 wheels. After three months of use, I was forced to replace the rear rim, which cost me $175 total ($45 to ship to CB and $130 for the rebuild, which didn't include new spokes). Add that to the $25 I paid to have the wheel trued twice by my LBS prior to sending it back to Crank Brothers.

I was told that the replacement was due to too many flat spots in the rim, so it wasn't covered under warranty.

I rode them for three and a half months on a 2012 GT Sanction, while I was guiding in Peru. They saw almost daily use during that time. All mountain enduro style riding is all they really saw. Wheels on the ground 98% of the time. Very few jumps or drops, but I landed them all smoothly on transitions when I did.

I liked that they were lighter than my previous wheelset. They are visually pleasing, and the design seemed legit. I didn't like that I had to completely rebuild them after three months. I used my last wheelset for the past six years, only needing to rebuild the rear wheel once due to a hub failure (Sun Ringle Abba hubs laced to Mavic 729 rims). Reviews and CB both said they were a super strong wheelset that would hold up to everything from XC to light DH, which I how I ride 90% of the time.

I can't say they never took a hard hit to a sharp edged rock (after a flat), but I can say that they didn't see anywhere near the use that my last wheelset saw (full on DH, jumping and 3-15′ drops, including to flat). I felt that the rims should have held up to the level of riding I was giving them.

I've since received my wheel back, but I'm not sure yet if I'll keep the set or sell, and purchase another hand built traditional wheelset. I was kind of turned off by the lack of warranty availability, but I have had good CS experience with them on two occasions in the past.

So I'm not sure I'm sold on this wheelset.

(I've also had bad luck with their tools, the chain breaker in general, and I find it frustrating that they do not give the public the information to rebuild the Joplin seatposts, but instead force you to ship it back to them, and pay for a rebuild)

Reply

Dirk

10 years, 5 months ago

Huh. Very interesting. Couple of questions.

By "flat spots"…do you mean spots where the wheel is out of round, or are you talking dings in the rim? It sounds like the re-designed rims are going to be stronger, but it's interesting to hear that you had an issue.

Ignoring shipping charges, $130 for a rebuild doesn't sound too out of line. Too bad your shop couldn't do the work.

Reply

PinkRobe

10 years, 5 months ago

Inside rim width is 21/23/26 for the Cobalt/Iodine/Opium. For the Cobalt/Iodine, this is roughly what the DT 4.1 and 5.1 rims were at 5+ years ago.

With regard to why bike wheels are the way they are, it's probably because the basic spoked design works pretty well. Light enough to be pushed along by human-scale power, but also strong enough to handle most human-scale stresses for years at a time. Having lots of spokes spreads the load around the rim, reducing the effect of a single point of failure. Fault-tolerance is a good thing. I can't imagine how you'd make a cast/forged wheel [like on a car] that would compete with a traditional bike wheel for strength at a reasonable weight. Carbon could work…?

I guess what bugs me about these wheels is that it's just style. Are these wheels really an improvement over traditional 32-spoke wheels? Are they really stiffer/stronger/longer-lasting than a regular wheelset that I can get for the same/less weight and money? It sure doesn't look like it to me…

Reply

Dirk

10 years, 5 months ago

He asked about inside diameter, not width. I guess he's concerned with how the tire will seat? And are you suggesting that the rims aren't wide enough?

Current spoked technology works well enough, yes. And no, I'm not suggesting that we need cast/forged wheels on mountain bikes. I'm just pointing out that there's some things about wheel design that are less than optimal. It is weird that you want a rim to run straight but you place stresses on it via spokes that pull in opposite directions. Seeing as you don't have to look far to read complaints about hub durability, yet I haven't read one single thing about a rim blowing up prematurely, they might be on to something. I would argue that wheels are the weak point on many a bicycle and worth a look.

Reply

PinkRobe

10 years, 5 months ago

My bad, I saw diameter and thought width. Kind of a reflex, what with the trend to ever-wider rims. I'd assume the diameter at the bead seat is "standard", and that the rim is slightly higher just outside the center channel. Hmmm. Might be tricky to mount tires if they're on the snug side.

I think the rim is one of the more failure-prone areas of the wheel. It takes a lot of effort to break a spoke, but denting a sidewall or putting a flat spot in a rim is pretty commonplace. The vast majority of hub failures I've noted aren't due to the "wheel" part [flanges, axles, body] failing, rather, they're an issue with the freehub/drive mechanism or a crapped-out bearing. If you trash your freehub, it doesn't affect the wheel's strength, just the drivetrain's ability to function. Remove the chain and you can still coast.

As for placing stresses on the wheel "via spokes that pull in opposite directions", it's because the spokes have almost no strength in compression. Something like a wagon wheel or a tri-spoke have strength in compression and tension, and don't need to rely on the same configuration as a spoked wheel. I'm not sure if this is what you're getting at, so we may be talking about different things…

Reply

Dirk

10 years, 5 months ago

Pinkrobe:

What I mean by "spokes pulling in opposite directions". Imagine your rim was a piece of rubber. The spoke tension would be pulling the rim into a sawtooth pattern - one pulling from the left, one pulling from the right. This creates internal stresses within the rim. This is not ideal. This is why truing wheels kind of sucks. You put a hop in a wheel in the same direction that a spoke is pulling and you have to put a heck of a lot of tension into the surrounding two spokes to pull it back.

Two spokes pulling in opposite directions at the same point is more stable. It will place less internal stress on the rim. In theory.

Reply

PinkRobe

10 years, 5 months ago

@Dirk

Gotcha on the opposite directions thing. Like anything else, it's a tradeoff. Fewer paired spokes requires a stronger [heavier?] rim to handle the higher load per spoke pair. OTOH, using lots of spokes would let you use a weaker/lighter rim [and potentially lighter spokes] 'cause the distance between spokes at the rim would be so short, and the resultant stress lower per spoke. The fact that most wheels use an extruded aluminum rim limits what you can do in terms of removing excess material, allowing one to keep strength whilst reducing weight. Perhaps 3D printing will yield a solution!

With regard to the wider rims, IMHO they are a wee bit on the narrow side. Personal preference of course. To me, it looks like they're playing catch-up…

Reply

Dirk

10 years, 5 months ago

I don't necessarily think this means that they need a stronger rim. It just means that they have to pay a bit more attention to a different failure mechanism. Theoretically:

Standard wheel with 32 spokes - More likely to develop lateral failure, less likely to develop flat spots due to closer spoke spacing (although, dealing with the lateral failure is more likley to result in flat spots)

Crank Bros. - Less likely to develop lateral failure, more likely to develop flat spots due to larger spacing between spokes.

I think that mountain bike wheels are far more likely to develop lateral hops than flat spots, so giving up a bit in that area to improve laterally seems like a good trade.

Reply

PinkRobe

10 years, 5 months ago

A few things:

- You need a stronger rim because of the higher load at fewer points on the rim. There's not really any way around it, paired spokes or no. Given two wheels using the same type and size of rim, the one with the greater number of spokes will be stronger. To create two wheels of equal strength, but with one having 32 spokes and the other 24 spokes [assuming similar hubs are used], the 24 spoke wheel must have a stronger/stiffer rim. Physics says so. So does Jobst Brandt, and he literally wrote the book on this stuff.

- A significant [more than a few mm] flat spot in your rim means you have bent it inwards towards the hub. Since your spokes can't resist this bending force [no strength in compression!], the number of spokes and their placement is largely irrelevant. If you want to unbend your rim, you can try your luck with any number of presses or pulls, hydraulic or otherwise.

- A less significant flat spot in your rim can be taken out by tightening the spokes on the opposite side of the rim and loosening the ones at the site of the flat spot. This is the sort of thing you do when building a wheel up with a new rim that's slightly out of round.

- Regarding a wheel going out of true ["lateral failure"], more spokes makes a wheel more resistant to this. That is to say, the wheel is stronger with more spokes. All other things being equal, a 32-spoke wheel is inherently stronger and more resistant to going out of true than, for example, a 24-spoke wheel.

Reply

cam

10 years, 5 months ago

Drew - the wheels are coming back with Dave and will receive a proper thrashing here on the Shore. We may even subject them to the Morgman. A Forum test would be a great idea as well.

Reply

The Big Picture

10 years, 5 months ago

What happened to 26″ cobalt 3, or the 26″ iodine 3. I wonder what these marketing guys are thinking. What are the inside diameters and wheel weights?

I have never taken these wheels seriously. Their tools look good and work not so well. Chain breaker under achievement.

Reply

Dirk

10 years, 5 months ago

Crank Brothers say they're seeing most of their sales in the larger wheel sizes and it didn't make sense to put a whole lot of development into 26 inch. Like it. Hate it. Chalk it all up to an over-arching industry conspiracy. Everybody is buying larger wheels. Especially on new bikes.

Reply

Andrew Major

10 years, 5 months ago

Very well written Dave.

Questions:

What type of drive mechanism does the hub use? Is it easily user serviceable? Are the wear surfaces replaceable, or machined into the hub shell? How many engagements?

What are the long term testing plans for these wheels? Most riders, thankfully, do not have experience with the original Crank Bros wheels -- in our (Sea-to-Sky) region their failures where legion.

If Crank Bros wants to sell wheels having sponsored pros ride them for miles in the sun, on dry trails, in Laguna is a poor test. If they were serious about showing improved longevity a forum test set-up (a la Specialized tires) where a number of riders - riding year round in our conditions - regularly report on what they are riding and how the wheels are holding up would ensure a multiple sample group.

Otherwise, I don't know anyone who could/would recommend these wheels with good concious on Crank Bros guarruntee that they are improved from the past <>.

-D

Reply

Dirk

10 years, 5 months ago

It's a pretty simple 3-pawl set-up. It all looked pretty easy to replace. Didn't see what the pawls engaged with, but I can't imagine it would be anything other than a piece of steel. Don't know the specifics on how many engagements and whatnot.

I wouldn't dismiss Laguna as a poor test. Trails are steep and rocky and more than willing to challenge the structure of that wheel. Interior riders will tell you that dust has it's own challenges to seals. Norco DH team runs these wheels as well, so it's not like there isn't exposure to broader conditions.

Reply

Uncle Duke

10 years, 5 months ago

hopefully better than their pedals….:(

Reply

Garrett Thibault

10 years, 5 months ago

I really like this write-up. I have a new attitude for those wheels, which I was actually just judging the other day.

I doubt I'm going to be getting on a set of crankbrothers wheels anytime soon though.

Buying a new wheelset is a rarity for me. I think I've bought two in my life, and the last purchase was only because it was $130 for both wheels. One thing going against complete wheelsets is that I generally only need one new wheel at a time. The other is that I have enough parts to my name now I can take a conventional hub that's laying around - or is hanging in a damaged wheel - and have it laced up to a new rim for a bit less than a new wheel would cost.

Reply

Please log in to leave a comment.